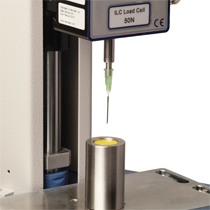

The medical devices and associated services industries are subject to strict quality standards testing. The complete life-cycle of the equipment is covered, including the safe disposal of used, contaminated items. Manufacturers of products involved with the safe discarding of medical devices with needles (‘sharps’) must conform to British Standards to provide proof against puncture by clinical waste materials. These sharps bins will be handled by staff from several organisations in the chain, not all specifically trained in medical practices, thus safety must be assured against the puncture of the container material by the waste. A puncture resistance testing process should allow a variety of sample types – specifically material thickness – to be securely located by means of an adjustable base fixture that has sufficient clearance to drive the needle point a certain distance through the surface of the standard diameter sample. An extension rod to fit the syringe hub is required for the crosshead fixture. Measurement of the peak force applied to create a breach can be achieved with computer controlled test programming and run from a touch screen console with each unique test associated with a sample type.

Mecmesin Systems: MultiTest touch-screen test system

International standards (ASTM F2132, BS 7320) specify the puncture resistance of medical sharps containers. By using real sharps on samples taken from containers, on a programmable universal test stand, repeatable and reliable testing is possible.

Mecmesin designed and provided a Luer hub fitting extension to attach hypodermic needles of various designs to a loadcell, and a tubular sample holder to allow undistorted full penetration of the container wall sample.

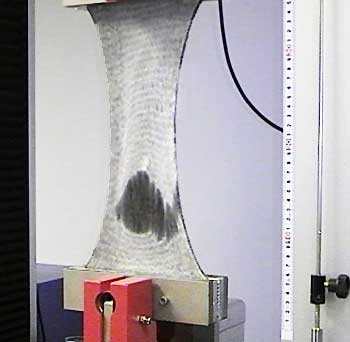

Geotextiles undergo a range of forces in their intended applications and determination of their suitability for in-service conditions involves a number of test types. The variety of materials utilised—both synthetic polymer and natural—and method and construction—woven, knitted or non-woven—means that quality testing requires consideration of the sample gripping, manner of deformation and loading capacity. Mecmesin has a range of force testing systems from mid-capacity single column configurations up to 50 kN twin column UTMs. A geotextile fabric may undergo forces which could stretch, tear, puncture or penetrate the membrane and an appropriate replication of the relevant loading is essential to quantify the performance of the textile in its environment. Typical international standards targeting these test types include: ASTM D4533, trapezoid tearing strength of geotextiles; ASTM D6241, static puncture strength of geotextiles and geotextile-related products; ASTM D4632, grab breaking load and elongation of geotextiles.