The food packaging industry has long had concerns about pinholes, flex cracks and leaks in the flexible materials and seals of retort packaging. A famous global food and drink maker needed to test the laminated retort packaging films that protect products such as their popular microwaveable stir-in pots.

Retort film is manufacturered from multiple layers of laminate foil and withstands extensive thermal processing to heat seal and sterilise food contents. This packaging method provides the product with shelf-stability, while giving consumers convenience and protection from harmful microorganisms.

Since blown seals or breaches in film can lead to contamination or spoiling that can cause food poisoning, this maker needed to run peel tests to determine the following:

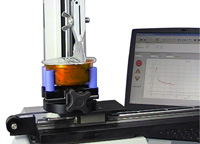

To obtain a reliable picture of the performance of their packaging seals, this maker selected a Mecmesin computer-controlled test system fitted with a custom-designed pull-peel table.

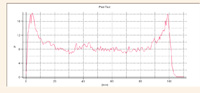

The Mecmesin system enables a 90 degree peel test. The pot-shaped container is held between four gripping pegs on a level base plate secured to an assisted peel table, and the container's foil tab is held by a flat-faced jaw grip. The table moves the container horizontally, against the direction of peel, at the same rate as the grip pulls the foil tab upward (150 mm/min). These synchronised motions cause the foil to be steadily peeled away at 90 degrees. The test stops when the foil is fully separated from the container. The advanced MultiTest 1-i system uses Mecmesin's Emperor™ force testing software running on a PC to record and display the performance of the sample during the test. Peak force is identified and a detailed graphical display of each test is presented, enabling identification of defects and locations of adhesive failure.

The result is improved consistency in adhesive application and foil-container seal quality, which lessons the likelihood of customer grievance and wastage.