3 parameters needed to be tested on a range of toothbrushes;

The equipment needed to be simple to operate for production staff, robust enough for a factory environment with extremes in temperature and offer the ability to perform all 3 tests with the minimum of 'set-up' time.

A VersaTest motorised test stand adapted with accessories and sensors was used to perform each test.

According to the ISO 8627 bristle stiffness test, the toothbrush has to be mounted in a holder and rubbed against a metal grid at a speed of 200 mm/min. The grid is attached directly to a 100 N S-Beam Loadcell which detects the stiffness of the bristles as they travel over it's surface. The graph of force/deflection was recorded using DataPlot-X software. Soft bristles will show a low force compared to hard bristles.

A surgical clamp with serrated jaws was used to hold the bristle for the 'single bristle' pull test. Forces in the region of 10-15N were required to remove the nylon bristle from the polypropylene toothbrush head.

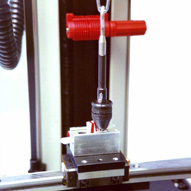

For the 'tuft' pull test, a set of bristles were held in a pin-chuck and connected to a 200 N S-Beam sensor, via a flexible chain link. Removal forces for the complete tuft were in the region of 50-70N.

Westone Products, UK & China