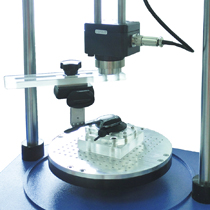

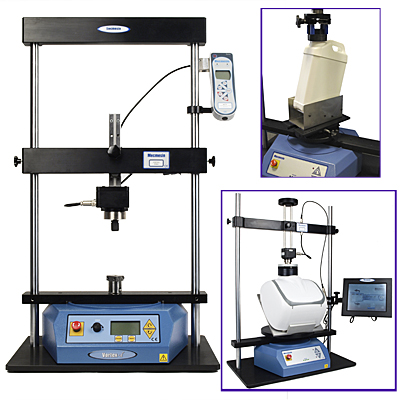

Manufacturers of golf shoes and aftermarket suppliers of replaceable cleats (also known as spikes), need to know that the cleats will remain in place under normal use, but can be removed for maintenance or replacement. In order to achieve consistent product quality, it is necessary to measure the breakaway torque as the cleat begins to rotate, and the maximum torque needed to fully release. In addition, when fitting the cleat the torque and angle at which the cleat locks or any over-ride torque can be determined. Up to ten cleats may be attached to the sole of the shoe and the ability to align each cleat with reference to the torque sensor is critical to the accuracy and repeatability of the test. A multipoint sample holder mounted on a gimbal coupled to an X-Y motion table is required to provide the range of movement needed to achieve correct centring. Top-load weights provide a constant axial force during measurement. A computer controlled stand controls rotation and collects torque and angular data. Modifying the control program for cyclic testing to assess any degradation due to repeated operation is a simple task.

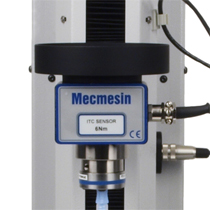

Mecmesin Systems: Vortex-i computer-controlled torque test system

The 6% conical taper Luer connector for syringes, needles and other medical devices can be push/pull taper only, or a taper and screw (“Luer lock”) fitting. Light assembly and disassembly torque to turn is required to seal so that even a child could use successfully, whilst remaining leak-proof. However, a successful seal at low torque improves at higher torque. In the case of Luer locks, torque assessment should be performed on a low-level torque testing system, with a motorized base plate and a low capacity (e.g. 1.5 Nm) torque transducer. The most common test involves tightening the Luer lock connection between a needle housing and a fluid-filled syringe to a pre-determined torque, and visually inspecting the joint for leakage. Universal gripping pegs may be used to hold the sample in place, although customized fixtures ensure greater accuracy and repeatability – keeping the sample concentric with the torque axis is an important consideration. A floating fixture, or similar, to allow secure location into the needle attachment component should also be employed. For in-house quality standards compliance, a semi-automated syringe tester using a touch-screen controlled torque testing system which can be programmed with acceptable limits for the syringe is recommended. The operator is presented with a colour coded pass/fail result for easy identification of the sample status.

Mecmesin Systems: Touch screen torque test systems, Emperor™ (Torque)

Video: Semi-automated syringe tester

White Paper: An Examination Of Needle And Syringe Force Testing

Electronic communication devices are designed to be comfortable and ergonomically efficient in their usage, especially in environments where the product may be worn for extended periods – for example by company contact centre agents. The microphone arm of hands-free headsets may be designed to deploy and stow as needed, and as such must do so in a precise manner with positive engagement, yet operate with a light enough torque to turn to not require excessive effort in prolonged, repeated use. The implementation of a computer-controlled torque test system provides a manufacturer’s Research and Development department with the flexibility to create a suite of test programs for an extended product range. Custom fixtures to attach to the torque cell may be built to accommodate a variety of designs (over or on-ear, wireless, Bluetooth) and sizes (mini, ear-clip or full-size over the head) to swing the component through its complete arc. An adjustable lower table fixture also must securely locate the body of the headset. Interchangeable torque cells will allow accurate measurement for various models – production or prototype designs. The software should be programmed to report the salient characteristics of the torque curve – peaks to initiate the rotation and locate the arm into the home position as well as the peak and average effort in the main stage of the actual rotation (running torque).

Mecmesin Systems: Conputer-controlled torque test systems, Emperor™ (Torque)

Case Study: Headset Microphone Joint Torque

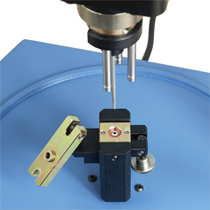

The 6% (Luer) lock-type of conical tapered connector, used in fluid delivery systems in the medical field, must ensure leak-free performance at all times. Whether in hand-held syringes or other devices, such as infusion pumps supplying nutrients or medication, the seal must remain intact so as to provide the exact dosage – and this unscrewing torque test evaluates the device’s resistance to coming apart. The testing standard for semi-rigid versions of Luer components requires precise assembly of the connector under inspection (male or female) to a metal reference fitting prior to performing the specific functional test - 27.5 N top-load and 0.12 N.m torque. Due to the light loading values required for these devices, a precision test stand is needed. The unscrewing torque test requires that a very small torque (0.02 +0/-0.002 N.m) is applied and then held for a minimum amount of time. Precise alignment is essential to ensure than no other forces occur along any other axis, and the test stand must be able to provide this level of control. The Luer connector must remain attached to the reference fitting to comply.

Mecmesin Systems: Helixa precision torque test systems

Applicable Standards: ISO 594-2, BS EN 1707, BS EN 20594-1 ISO 80369

White Paper: An Examination Of Needle And Syringe Force Testing

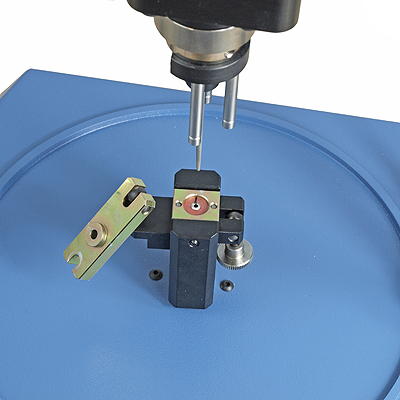

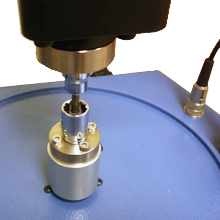

The components in rotating machine tools which are designed to work on materials, need to remain securely located in order to accurately wear the target surface. Small abrasive disks used in the dental industry (to shape implants), should be tested for integrity by evaluating their resistance to an applied torque to turn created between the implant surface and the driving spindle of the tool. Using a custom-designed adaptor, the abrasive disks may be tested to check that they do not become loose on their central hub when in service. Should the breakaway torque be less than required standards, the supplied batch can be rejected. The disks are marked clearly prior to being loaded onto the adaptor to show any subsequent rotation. The adaptor securely clamps the abrasion surface itself and a custom probe is lowered into the spindle bore. The software program rotates the locked probe 90 degrees clockwise and 180 degrees anti-clockwise. If the disk has rotated in the hub, then the component fails. Slippage around the spindle or rotation against the fixing (much less likely) would show no indicated disk rotation. The torque is measured and the test results graphically displayed to further quantify the level of discrepancy between specification and achieved peak torque.

Mecmesin Systems: Vortex torque test systems, EmperorTM (Torque)

Video: Dental abrasive disk testing

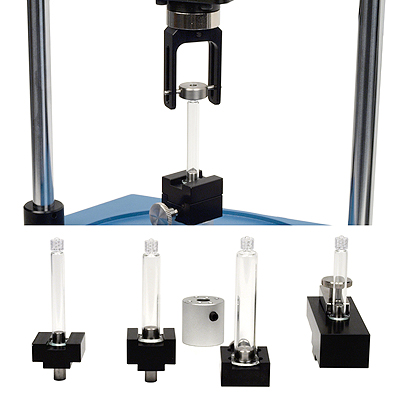

Our client manufactures glass syringes with compression-fit polycarbonate Luer lock adapters. Quality testing requires measurement of the torque required to rotate the adapter, to ensure it cannot come away under normal use of the Luer connection. The syringes come in various sizes, so a flexible range of grips was required.

Mecmesin met their needs with customised grips to hold the glass syringe barrel, and to grip the Luer adapter to turn it, with perfect axial alignment.

Luer lock test standards frequently involve the application of a simultaneous and prescribed axial force. Our client required fastening and removal torque of caps from from syringes without this. Precision measurement of the torque to fasten and remove the cap needed a simple custom solution.

Two parts, to grip the syringe base and to engage the Luer lock cap, were designed by Mecmesin, and allowed rapid exchange of samples for accurate and repeatable testing at maximum efficiency.

Endoscopic and laparoscopic surgical instruments are operated by axial and rotating adjustments in the handle, to perform precision movement in the head. One manufacturer asked us to provide test fixturing for the operating torque of a laparoscopic instrument in two controls, to splay and to flex the head.

Mecmesic adapted one of its Vortex-xt torque testers by extending its column height to accommodate the instrument length. By fixturing around the length, and gripping the twist controls in the handle, each manipulation could be independently tested for required torque to turn, and smoothness of operation.

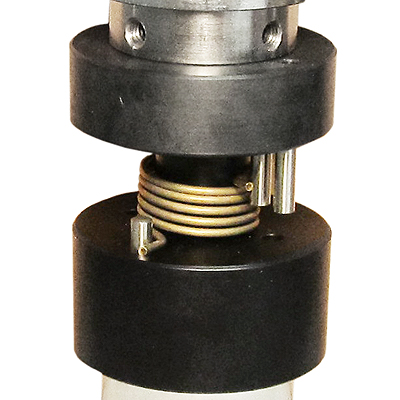

A manufacturer of torsion springs approached Mecmesin for a set of custom mandrels. Torsion springs require central core support, and turning pins to engage a wide variety of leg ends.

We regularly design custom torsion spring cores and mandrels to client specification, for operation on our Vortex and Helixa (precision) torque testers.

A manufacturer of hygienic disposal bins came to us with a nappy (diaper) disposal unit with a rotary intake mechanism. The bin was 30 cm wide and the opening at 45 degrees, making holding of the bin for proper axial rotation somewhat difficult.

Mecmesin designed a rotating platform at 45 degrees to rotate the bin about the axis of the rotating mechanism, but the width required an additional modification of our standard Vortex torque tester for increased column separation. The result was a tester for rapid and effective, repeatable testing to ensure consistent quality of the manufactured units.

Sometimes a client approaches us with a range of requirements for a number of their products. Using their universal testers for a variety of testing, they also need custom and versatile fixtures. Cosmetics packaging, for example, frequently combines design-led profiling with light handling, as in mascara tubes and brushes, attractively-curved lotion containers, and lipsticks. Some of these imply very light rotational torque, others maximum strength in lightweight design, for daily use.

Mecmesin custom grips assure axial alignment, secure holding and minimal deformation that might adversely influence test results and repeatability. In this example, compression, tensile strength and torsion strength were addressed in a suite of fixtures for a variety of popular products.

A global supplier of medical equipment manufactures small dental abrasive disks. They needed to test the integrity of the riveted hub, for the torque at which it could begin to rotate in the disk. Clamping the abrasive disk whilst applying torque to the very small hub presented a particular challenge.

Mecmesin devised and supplied a custom fixture for rapid quality batch testing of different sizes of disk on a programmed Mecmesin Vortex torque tester. A clamp secured the outer disk, and a conical probe engaged the hub by friction. By rotating each test sample 90 degrees in one direction then 180 degree in the other, marked samples would clearly show rotation of the hub against the abrasive part.

Adlens manufacture adaptive spectacle lenses, where the optical power is adjusted by a side dial which is then removed. Among other tests, they needed to measure the running torque and rotation to destruction of the dials, to test for smooth running and consistency. An essential element in such low-torque testing is concentric alignment for detection of imperfections.

A Vortex-i torque tester with Emperor software was fitted with a custom fixture to support the lens piece, whilst a custom-moulded mandrel engaged the adjustment dial. The fixture pair enabled adjustment for accurate alignment, repeatable testing and detailed examination of the dial rotation quality.

Plastic bottle caps and T-corks have individual profiles for finger gripping, and the best way to torque-test their performance is by providing an exact machine grip at as many points as possible. Many well-known brands and manufacturers come to us for custom-profiled mandrels to use on their torque testers.

A custom mandrel is much quicker to place and release than a screw-fit clamp, and by precise positioning offers true repeatability in testing of bridge torque, removal torque and running torque.

The helical torsion spring comes in a wide variety of sizes and finds use in a diverse range of industries. Spring loaded componentry in home and consumer goods: clothes pegs, clips and old-fashioned mousetraps; small doors and flaps on cameras or hi-fi equipment; large doors and closures such as those on garages or gates and in transport applications like vehicle luggage compartments. Calibrating the torque to turn (running torque) of the torsion spring is required to achieve the desired levels of effort for the user to open/close the component and provide the optimum levels of resistance or snap. The ability to test a range of products requires a set of custom fixtures to match the spring design, for example spiral. A lower rod-shaped mandrel holds the spring and the upper fixture incorporates a drive peg – directly connected to the torque cell – which locates into the outer arm of the spring to load and unload the sample. Computer control with a suite of test programs can rotate the spring to a pre-defined angle and collect the torque and rotational displacement data continuously. The software ensures repeatable testing of clockwise or anti-clockwise turn (approaching the design load point from below and above, then averaging, minimises the effect of friction and hysteresis on the results) and can guard against permanent set in the spring material. The requirement to meet specific torque range limits – within the linear response range of the spring - can also trigger immediate PASS/FAIL indication as the results are recorded and displayed.

Mecmesin Systems: Vortex computer-controlled torque testers, Emperor™ (Torque)

The helical torsion spring comes in a wide range of designs and varying sizes to cover almost every engineering application. Despite being termed ‘torsion’, the spring itself is subjected to a bending stress when the ends rotate about its central axis, driven by the components attached to either arm. The elements which are required to rotate in service depend upon the spring’s stiffness rating in order to be fit for purpose and also exhibit the correct level of resistance for ease of operation and quality feel. The smallest examples, used in precision applications, need to employ a test system which can not only ensure that the spring’s axis remains aligned to within tight tolerances but that can accurately measure the resulting very light torque values. In these implementations, the frictional forces experienced by the coils may have significance. A spring design with pitch between the coils, rather than close-wound, will counter this issue and allow for even lighter torque to turn efforts, increasing the need for a torque test system capable of measuring these values. Exacting alignment of the fixture (hence spring) and torque cell axes for concentricity should be a capability of the test stand to guarantee the most accurate data.

Mecmesin Systems: Vortex computer-controlled torque testers, Emperor™ (Torque)

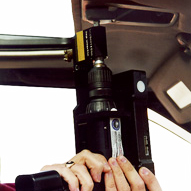

Measuring the torque required to wind sunroofs and manually operated windows in vehicles requires portability when the requirement is to evaluate in-situ. Such a test system could be implemented on the production line to provide quality assurance at the point of assembly. Measuring the starting (torque to turn) and running torque in both directions can be achieved with a digital torque indicator connected to a rotary torque transducer mounted on a standard cordless screwdriver. With the addition of a custom designed bracket, the bespoke system is self-contained and convenient to use on multiple locations round the vehicle.

Mecmesin Systems: Advanced force and torque indicator

Case Study: Window and sunroof torque

In order to meet internal testing requirements of a major automotive manufacturer, Mecmesin designed a system to measure the torque to turn input to a vehicle steering system. A custom-designed rig, fitted over, and attached to, the standard vehicle steering wheel, enabled the vehicle to be driven as normal. The Advanced force and Torque Indicator (AFTI) gauge displayed the torque value on the display in front of the driver. This system allowed the steering column running torque to be continuously measured in-situ, as part as an overall development process in steering system design, manufacturing and testing. The data capture and communication capabilities of the portable AFTI enable measurements to be taken in restricted spaces and more sophisticated analysis to be performed subsequently if required.

Mecmesin Systems: AFTI Advanced Force and Torque Indicator, Customised applications service

Vehicle cockpit controls must operate with ease, positive engagement and with a tactility that conveys quality and confidence. Many controls are multi-functional and incorporate mechanisms that move both axially and rotationally. Lighting and wiper stalks rotate about the steering wheel axis to switch on or off and also about their own axis to control additional adjustable settings or auxiliary functions. Mecmesin's range of torque testing products and extensive range of versatile grips allow these torque values to be measured accurately and repeatably. Important attributes may comprise the initial breakaway torque to initiate the rotational movement and the subsequent running torque to complete the actuation. Manual torque testers easily enable a user to operate the control as they would in the vehicle to quantify the human perception. Our motor driven software-controlled systems can be programmed to run the exact same test again and again for QA testing against standard values.

Mecmesin Systems: Motorised torque testing systems, Manually operated digital torque testers

Luer fitting slip, running torque and force testing

Luer fitting slip, running torque and force testingLuer lock and Luer slip fittings commonly attach hypodermic needle hubs to syringes and other fluid transfer medical devices or laboratory instruments to provide leak-free connections via a 6 percent taper at the joint. Both the threaded and friction types must require a high enough torque not to disassemble in operation and still maintain the hermetic seal, whilst still allowing easy and quick engagement/disengagement of the connected system. Breakaway and running torque tests are the means by which these performance criteria are evaluated. The quality assurance testing of mass-produced medical Luer slip and lock fittings demands precise control of concentricity at extreme low torques which is facilitated by the use of specific fixtures for accuracy and repeatability – industry standards often stipulating that the sample be assembled to a particular precision steel reference fitting. The Ease of Assembly test requires the addition of an axial force in conjunction with the rotational force, and a testing system which allows the precise application of this force is essential. The Unscrewing Torque test ensures that the Luer connection can be unscrewed with minimum trauma to the patient.

Mecmesin Systems: Helixa precision torque test systems

Dosage pen dosage dial torque testing

Dosage pen dosage dial torque testingThe medical industry demands that the administration of dosage requires the correct dosage to be injected for the individual patient. The rotational dial of an dosage pen’s dosage regulator must turn easily but positively enough to allow the correct number of dosage units to be accurately delivered from the disposable multiple use cartridge. In order to test the light breakaway and running torque values required to operate the dosage dial, it is essential to eliminate friction and position the sample with absolute concentricity. A torque tester that features a counterbalance to negate the axial force of the grip and torque cell in addition to precise adjustability of the alignment between the torque cell and the spindle is required. Fixturing for the sample should also ensure that it is maintained in an upright position.

Mecmesin Systems: Helixa precision torque test systems

Aerospace vibration resistant nut cycle testing

Aerospace vibration resistant nut cycle testingThe design specification of fastening components such as nuts, bolts and rivets is a complex task, particularly in extreme engineering environments such those encountered in the aerospace industry. The influence of temperature, corrosion, fatigue and particularly vibration are significant factors affecting the reliable and safe performance of the joint. Nuts which are resistant to vibration loosening through provision of prevailing torque are one key design solution. Cyclic testing of the bolt and nut fastening may be achieved with a computer-controlled torque test stand, which is able to accurately and repeatably measure the resistance torque as the nut is tightened and loosened. Should the measured torque to too high, then wear rates would be excessive, too low and the nuts would back off too easily and risk compromising the integrity of the joint. The capability to capture the data throughout the multiple cycle test program and the reporting of the characteristics graphically provides greater understanding of the forces at work, an insight into the fatigue life of the fastener design and increased confidence in the quality assurance process.

Mecmesin Systems: Vortex-i computer-controlled torque test system

Closure torque testing involves a range of tests for events designed into screw caps, lids and unthreaded stoppers. It can include a measure of the turning force required to initiate twisting, possibly to overcome safety features (e.g. CRC Types I and II) and tamper resistance features, and also to secure the closure. Other rotational systems, for example bearings, also benefit from the evaluation of the required torque to turn—both breakaway and running torque. Accurate measurement of the torque characteristics of these systems requires alignment of the rotational components with the grips and fixtures of the testing equipment. In the case of large or irregularly shaped products, custom designed fixtures may be needed to assure concentricity of the closure with the crosshead, and permit adequate clearance throughout the complete angle of rotation performed in the test.

Mecmesin Systems: Vortex torque testing systems with customised testing fixture design