Test Summary

ASTM D3330 Method gives a measure of the adherence of pressure-sensitive adhesive (PSA) tapes. Single-coated PSA tape has a backing substrate and the adhesive on the opposite side of the tape. Double-sided tapes have adhesive on both sides of a carrier substrate and utilise a release liner – which may also be employed on single-sided tape. Adhesive-transfer tape retains no substrate – the liner releasing to leave only the adhesive transferred to the adherend.

The standard covers 5 methods (A though E) at 180 degrees and 1 (Method F) at 90 degrees, which are applicable to single-coated, double-coated and adhesive transfer tape varieties. The type of tape determines the relevant test adhesive, as indicated in the table below:

|

ASTM D3330 |

PSA Tape |

Adherend |

Adhesive

|

Adherend 2 |

Adherence |

|

A |

Single |

Panel |

Face side |

Backing |

Backing |

|

B |

Single |

Backing |

Face side |

Backing |

Backing |

|

C (Face side) |

Double |

Panel |

Face side |

Film |

Face side |

|

C (Liner side) |

Double |

Panel |

Liner side |

Film |

Liner side |

|

D (Double-coated) |

Double |

Panel |

Liner side |

Liner |

Liner to |

|

D (Lined single-coated) |

Single |

Panel |

Liner side |

Liner |

Liner to |

|

E (Face Side) |

Adhesive |

Panel |

Face side |

Film |

Adhesive |

|

E (Liner side) |

Adhesive |

Panel |

Liner side |

Film |

Adhesive |

ASTM D3330 Test Method, Applicable PSA Tape and Adherends

Note: The panel may be replaced with an appropriate material of interest

Click here for more information on test Method A, which covers the location of the sample and the peel test procedure method which is common all of the 180 degree methods once the specimen preparation is complete.

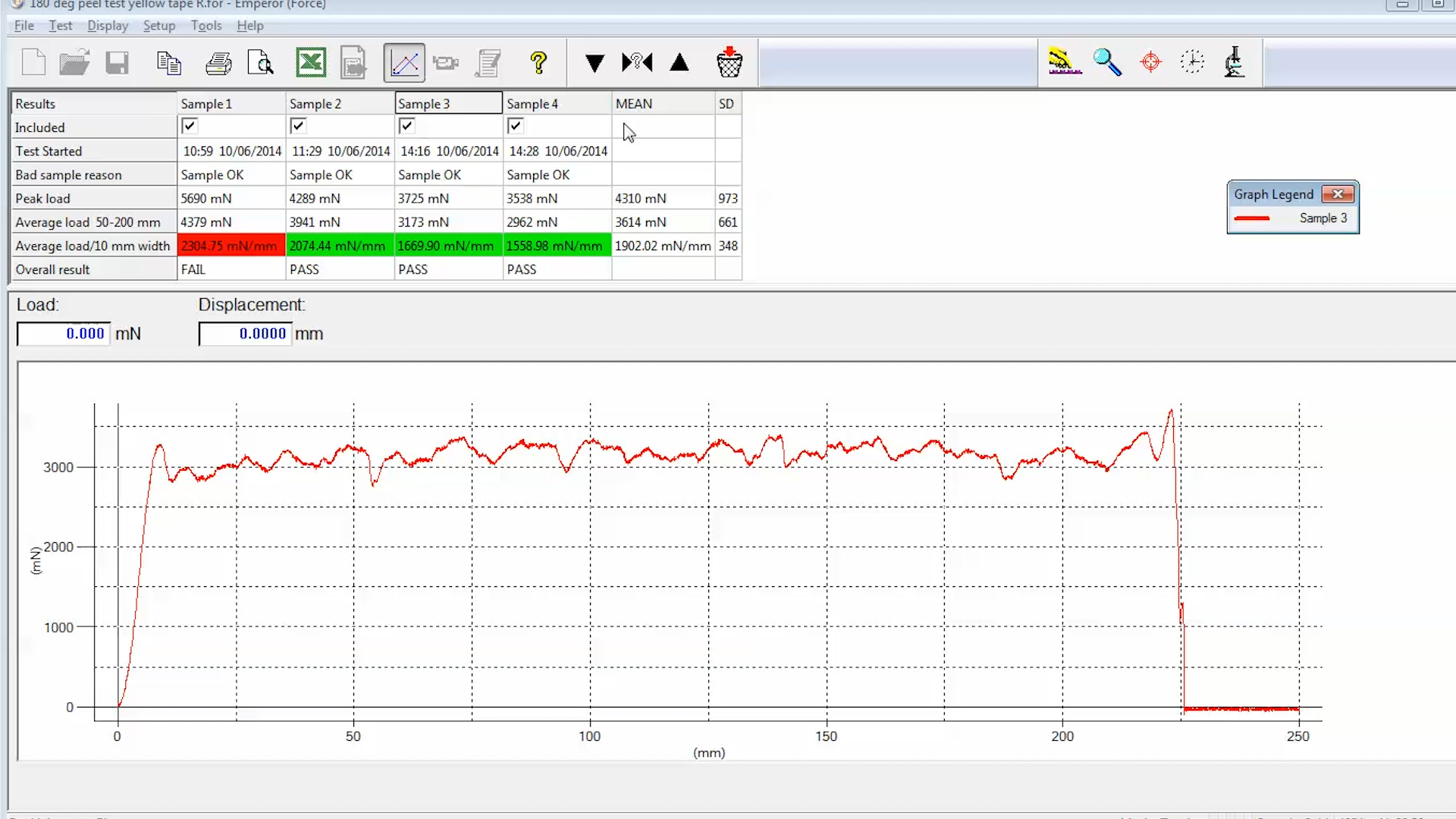

For each D3330 test method, once the sample preparation is complete, there will be a strip of material (adherend 2 in the table) which is then peeled from adherend 1 at a 180° angle, at a constant rate for a specified peeled length of the sample. The force required to effect the peel is measured and the average value calculated over the valid peel distance, which is used to calculate a peel adhesion value.

The common practice is to test at least 5 specimens from a particular tape product.

Test Apparatus

As for Method A plus thin polyester film, which is required to create an adherend which can be physically gripped

For each method, the sample preparation is very similar to that of D3330 Method A, with additional steps to facilitate obtaining the appropriate adherends and hence adhesive [layer] to peel test.

Method

The test method, in terms of applying the grips and running the adhesion tester and performing the calculations are identical to that of Method A.

Please refer to the latest official ASTM D3330 standard for more detailed information. This overview is intended to provide a basic understanding of the test procedure and suitable equipment to meet the standard.

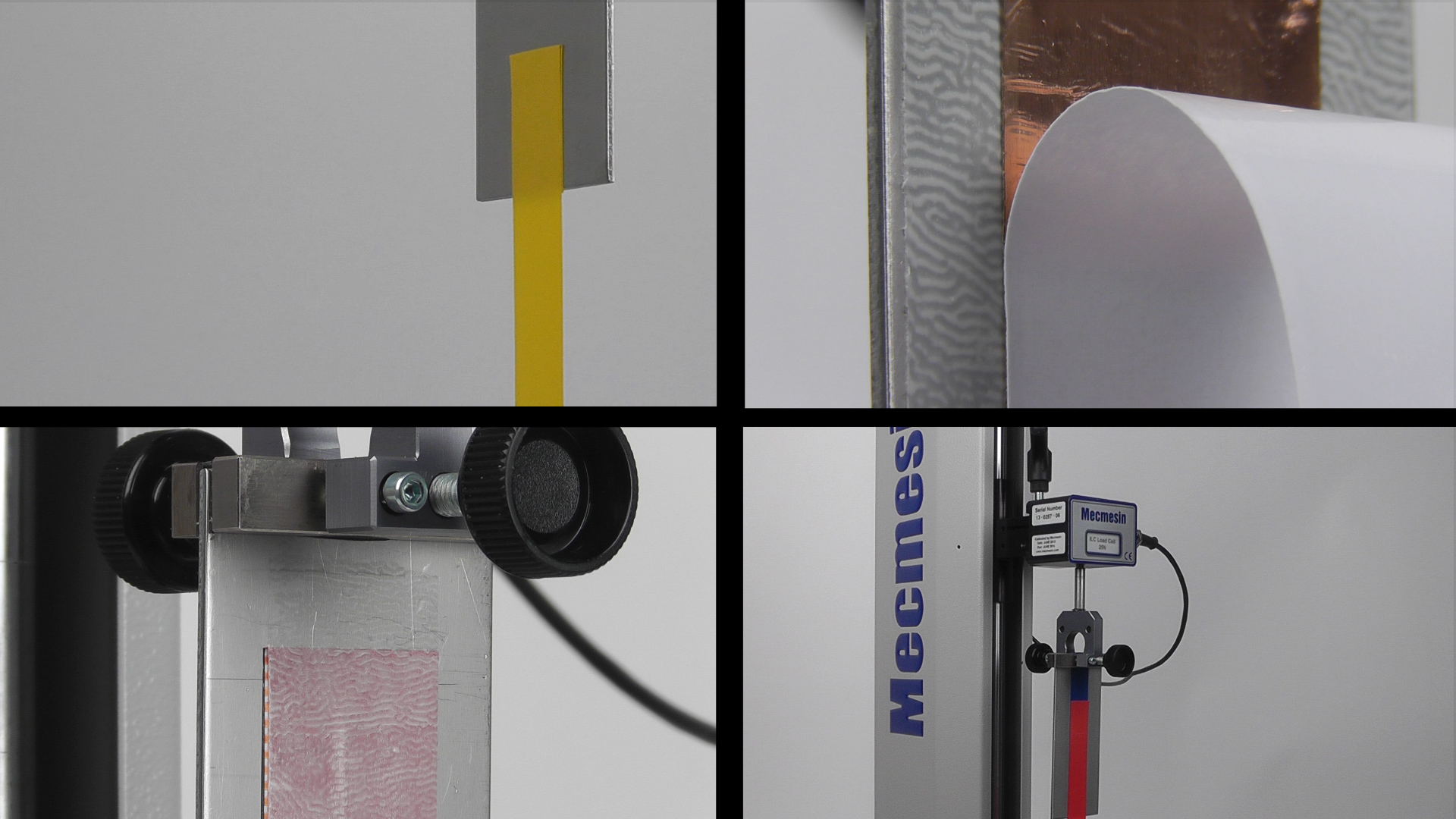

ASTM D3330 180 Peel Test Methods Video

Clockwise L-R from top left: ASTM D3330 Methods A, D (Liner Side), B, E