Fastening Torque Testers

Fastening Torque TestersBolts and screws secure many constructions, and the equal integrity and performance of each is crucial. They are often secured to a specified torque or number of rotations, such that a residual torque prevents loosening, but is not so much as to cause future strain failure in the component. Fasteners can be tested for their tensile strength, but under a full test rotation a ‘process signature’ can be obtained using a programmable torque tester. This will detect any variations in torque that indicate departure from specification such as misthreading.

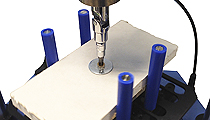

Our top-of-the-range Vortex-i torque testing system gives optimum testing performance and evaluation options, enabling you to get the most from your test measurements.

Our top-of-the-range Vortex-xt torque testing systems enable fast and efficient testing on the production floor.

Mecmesin’s Helixa torque tester provides the ideal solution for measuring low and medium torque variations on a variety of delicate or finely-engineered products. Its sensitivity and precise alignment make it suitable for testing high quality assemblies such as those found in the cosmetics, jewellery, pharmaceutical and medical industries, as well as finely-engineered parts requiring precision alignment during test.

Available also as a touch-screen model, the Helixa-xt, with all the same features but the convenience of a self-contained unit.

Our entry-level Vortex-dV test stands are a cost-effective solution for straightforward fastening torque tests.

The Torque Wrench Calibrator combines a universal display, Mecmesin’s AFTI, with a dedicated transducer to assess the torque applied by ‘click action’, ‘break back’ or dial torque wrenches up to 1000 N.m.

A versatile testing instrument, the TWC offers a choice of three operating modes:

Related test types: Pull-off-Pull-out, Tensile strength, Torque to Turn