Top load – non vented

Top load - vented

Top load – filled & capped

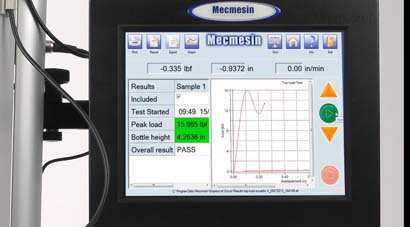

Top-load – non vented. Test to withstand counter pressure during lift cylinder filling and capping operations.

1. Select at least 12 empty bottles aged at least 72 hours

2. Compress with a non-vented steel compression plate at 510 mm/min (20 in/min) to 3.75 mm (0.15 in)

3. Record maximum load at 3.75 mm (0.15 in) or deflection and load if this occurs before 3.75 mm (0.15 in)

4. Record where bottle failed e.g. crushed foot, shoulder dent etc.

Top-load – vented. Test to withstand pressure during normal warehousing.

1. Select at least 12 empty bottles aged at least 72 hours

2. Compress with a vented steel compression plate at 510 mm/min (20 in/min) to 3.75 mm (0.15 in)

3. Record maximum load at 3.75 mm (0.15 in) or deflection and load if this occurs before 3.75 mm (0.15 in)

4. Record where bottle failed e.g. crushed foot, shoulder dent etc.

Top-load – filled & capped. Test to withstand warehouse stacking.

Motorised force testing stand – MultiTest-xt or Mul;tiTest-i

/multitest-2-5-xt-2-5kn

Loadcell of appropriate range – e.g. 1000 N

Vented and non-vented compression plates

/grips-and-fixtures

Please refer to the latest official isbt standard for more detailed information. This overview is intended to provide a basic understanding of the test procedure and suitable equipment to meet the standard.