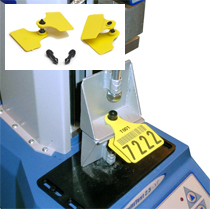

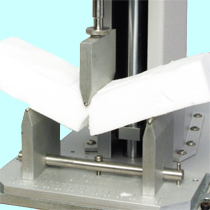

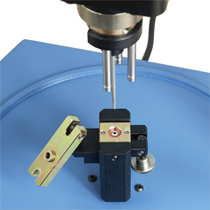

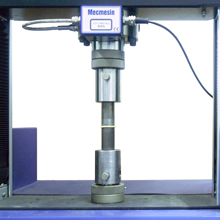

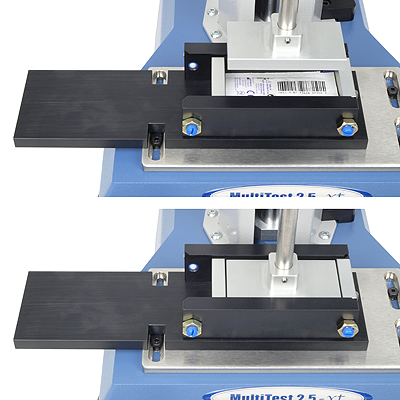

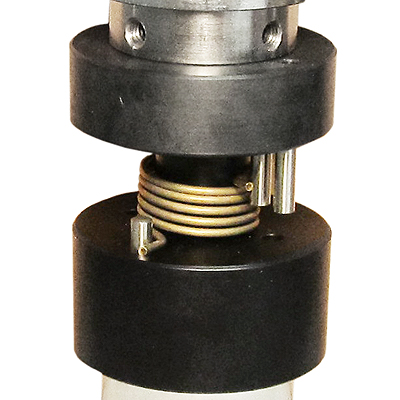

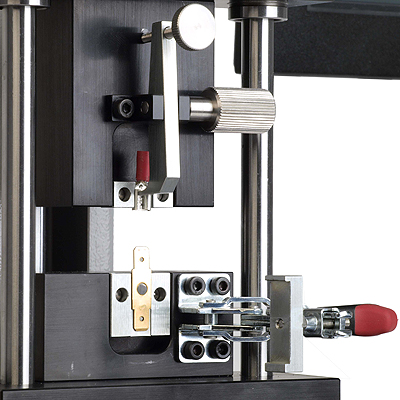

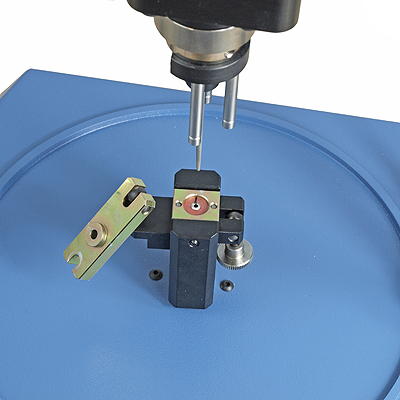

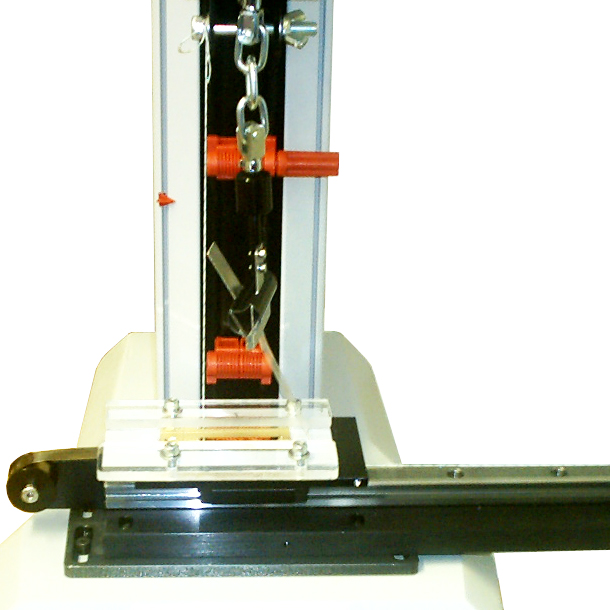

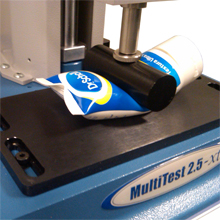

Animal identification tags are important for both legal and health & safety reasons where animal by-products are sold into the human food chain. The tags on dairy cattle are used to record data and trace the animals throughout the milk production process. The tags themselves, attached through the livestock’s ear, comprise of two flexible plastic leaves and a tamper-proof pin fastener. They must remain on the animal – and complete in themselves – when subjected to all expected in-service forces. Specific standards require testing for both tensile strength (by means of a transverse pull test) and pull-off/pull-out forces along the axis of the pin. The software–contolled test stand is able to hold the tags at a target load and then pull further at contolled speed (typically 500 mm/min) until breakage. Once failure occurs, the tags must be unusable as part of the traceability requirements. The transverse pull test can be performed with suitably rated tension wedge grips. The pull-out test on the pin can be achieved with custom grips designed to pull axially and support the leaf surfaces.

Mecmesin Systems: MultiTest console-controlled force test system, 5 kN wedge grips

Case Study: Animal Identification Tags

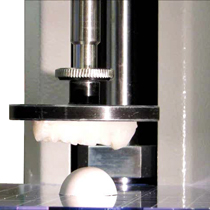

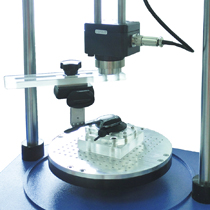

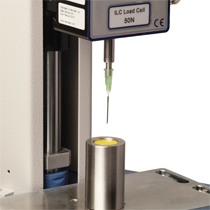

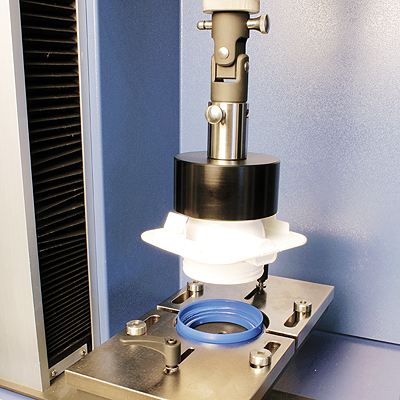

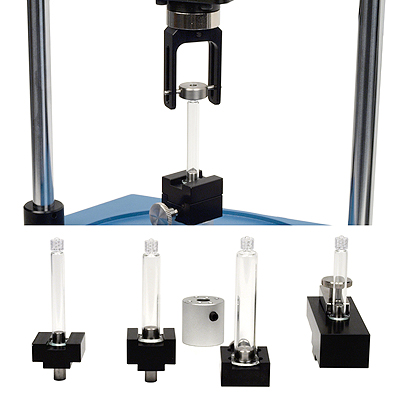

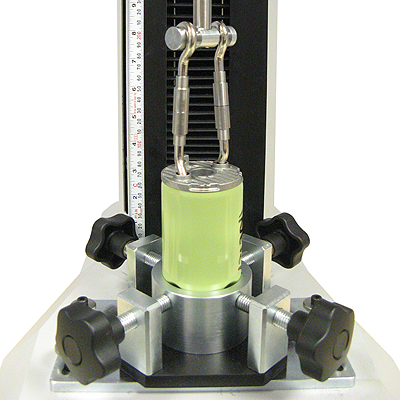

Scientific research in the sphere of physiology, anatomy and medicine has far-reaching impact on the health and well-being of humankind. The methodical application of testing and investigation into how biological systems behave and react to change allows the furtherment of medical science. The discipline of dentistry can employ mechanical testing to evaluate the bite strength of the mandible/maxilla system throughout the aging and wearing process, by repeatable compressive strength tests. One specific example uses a computer-controlled test stand to compress a plaster of Paris dome-shaped sample (which has comparable mechanical properties to hard, brittle food items, like nuts) to measure ultimate bite strength. Dental model attachments to the compression plate represent the tooth profile within the jaw and in addition to the force measurement, further evaluation of the fractured sample – size and number of fragments - also influence the scientific appraisal of mechanical performance. As the teeth wear, the profile changes and the effectiveness over time of the ability to fracture the foodstuff can be determined. The test program records the peak force at fracture and uses stop-at-break functionality to avoid damage and reset, then the output data is further analysed in Excel® - allowing the flexibility to continue research out in the field, by use of portable computers. The Emperor™ software’s ability record all of the data is invaluable in the thorough understanding necessary in a scientific project. Furthermore, this ethical engineering solution negates the need to experiment with living primate specimens.

Mecmesin Systems: MultiTest computer-controlled force test system, compression plate accessory

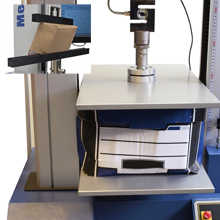

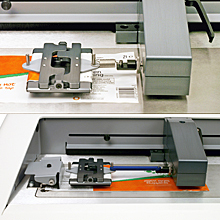

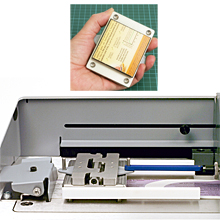

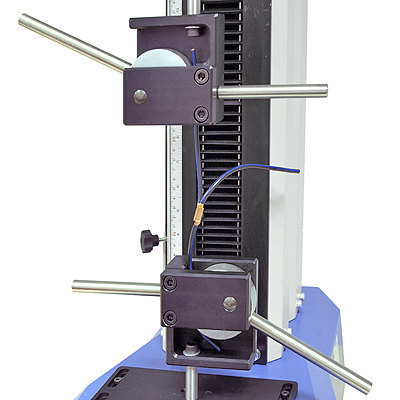

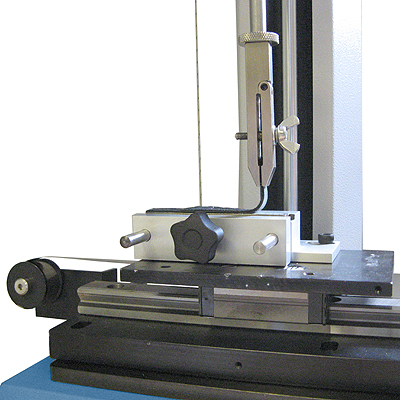

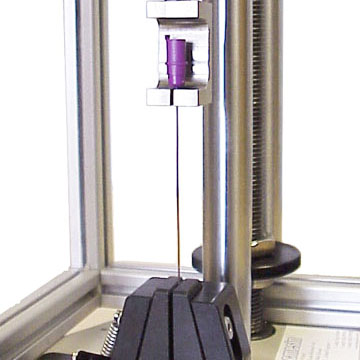

Products with bonded layers such as laminated security or ID cards undergo peel testing to check the integrity of the adhesive attaching the coating. Businesses in the home and office sector or manufacturers within the adhesives and coatings industries should quality test to these standards. A 90 degree peel test is applicable for samples where a more flexible bonded layer is pulled off a stiffer substrate at a right angle in order to determine the minimum force to peel the laminate. The test equipment must ensure that the 90 degree pull angle is maintained, with the substrate remaining horizontal and travelling laterally by means of a floating roller fixture or a moving peel table. The rigid substrate may negate the need for the support of a table, as in the case of a laminated ID or credit card. Flat jawed wedge or vice grips are needed to securely hold the coating layer throughout its vertical movement.

Mecmesin Systems: MultiTest motorised test system

Case Study: Delamination peel test

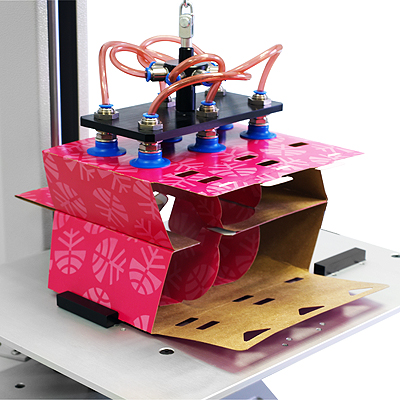

International sports organisations are responsible for the regulations governing their field of interest and these may cover a wide range of unique requirements. The sport of tennis has a number of court surfaces and also player levels from recreational through to professional which determine different criteria in terms of tennis ball characteristics. The fundamental performance measure of a ball is the bounce behaviour and this is directly influenced by its compressive deformation, size and weight. A customised automated computer-controlled system which is able to pick an individual ball and perform the compliance test, without human interaction, whilst capturing the results to generate a statistical report can then become an official approved test standard. In terms of the test specification for a tennis ball, the program steps include touching on the surface, exercising scragging before measuring the force through compressing to a specified ‘forward deformation’ (and relaxation) in 3 orthogonal axes. The process involves complex steps involving holding to certain load levels for certain amounts of time plus diameter and weight measurement. Challenges such as physically picking the next ball and moving the supply along require bespoke engineering solutions involving pneumatic grips able to grasp and to rotate to XYZ alignments, custom compression plates, a carousel dispenser and digital scales.

Mecmesin Systems: Customised force testing applications, Emperor™ (Force)

Case Study: Automated ITF tennis ball tester

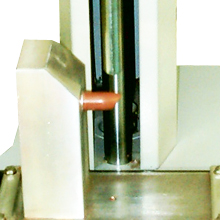

The important attributes for cosmetic products are related primarily to aesthetics and texture. Colour depth, choice of lustrous shine or matte finish and the feel of the product upon application to the skin, for example, are key selling points for lipsticks. Of equal importance (but less obvious to the consumer) is the durability of the cosmetic through repeated application – influenced by composition. The bullet-style dispenser for lipstick must perform reliably under cantilever-type flexure loading through forces applied by the lip at the tip of the bullet, and resisted at the end of the barrel container. The test system must replicate the conditions under which the lipstick will be stressed – holding the dispenser firmly and applying the force with a special fixture to ensure the sample will break due to bending force rather than being cut. The lipstick may fail either in shear or by the classic pure bending compression/tension force distribution: this test will determine either characteristic in the sample. By repeatability and accurately measuring the peak force at break, the manufacturer is able to evaluate the effect of formulation changes upon the performance of the product, either for aesthetic reasons: improving colour, finish and texture, or for manufacturing changes such as using different raw materials. This bend test is also applicable to differing designs of the lipstick tip – bullet, bullnose or chisel – due to the design of the fixture.

Mecmesin Systems: MultiTest motorised test system

Case Study: Lipstick bullet breakage test

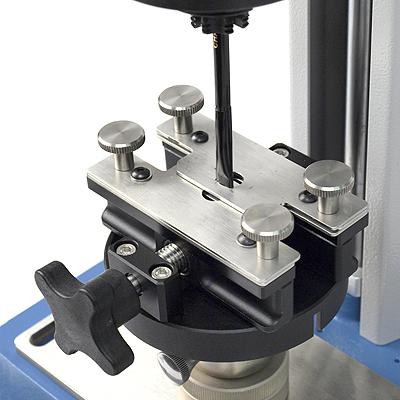

Manufacturers of golf shoes and aftermarket suppliers of replaceable cleats (also known as spikes), need to know that the cleats will remain in place under normal use, but can be removed for maintenance or replacement. In order to achieve consistent product quality, it is necessary to measure the breakaway torque as the cleat begins to rotate, and the maximum torque needed to fully release. In addition, when fitting the cleat the torque and angle at which the cleat locks or any over-ride torque can be determined. Up to ten cleats may be attached to the sole of the shoe and the ability to align each cleat with reference to the torque sensor is critical to the accuracy and repeatability of the test. A multipoint sample holder mounted on a gimbal coupled to an X-Y motion table is required to provide the range of movement needed to achieve correct centring. Top-load weights provide a constant axial force during measurement. A computer controlled stand controls rotation and collects torque and angular data. Modifying the control program for cyclic testing to assess any degradation due to repeated operation is a simple task.

Mecmesin Systems: Vortex-i computer-controlled torque test system

Keypad push-buttons are important componentry on many electrical and electronic products. Mobile phones, keypad entry systems or industrial machine controllers all have functional reliance on the reliability and longevity of these components. Testing the life-span for the keypad through repetitive actuation of the buttons requires automation to repeat the compression test cycle to either failure detection, a measured drop in the value of a significant parameter, or a specific number of cycles – at which point the component may be inspected visually and for degradation in functionality. A simple force gauge may be used to determine appropriate loading. The added flexibility of being able to specify the correct compressive force for different keypad implementations can be programmed into a software-controlled system.

Mecmesin Systems: Digital force gauge, Emperor™ (Force)

Case Study: Mobile Phone Keypad Life Test

Textiles, cloths and fabrics used in both clothing and sporting markets have requirements for flexibility and lightness, but also durability and resistance to breakage – particularly tear damage – when in use. A hot air balloon manufacturer must conform to strict standards, applicable to the aerospace industry despite the textile construction of the product. The variation in coatings for the fabric – due to individual designs – and the fabric itself, requires that the test procedure must be applicable all cases. The strip method tear test for fabrics evaluates tear propagation resistance under constant loading at a constant rate of displacement. For secure retention of the standard size samples, wave-form jawed grips would be suitable, capable of holding the fabric across its full width, up to forces of up to a peak of 350 N, in this case. This tear test may be used as a standard method for measuring the effect, not only of wear-and-tear on the textile, but the impact of sunlight aging the material over time. The same system of a motorised test stand, digital force gauge and results analysis software, plus the versatile grips can also be used to measure the tensile strength of the numerous seams and fastenings of the fabric structure.

Mecmesin Systems: Motorised stand with gauge and software, large vice grip

Case Study: Balloon Cloth Tensile Strength Test

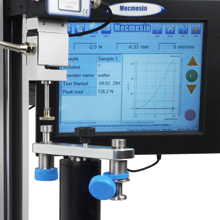

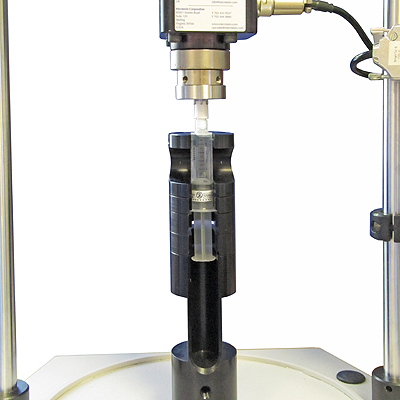

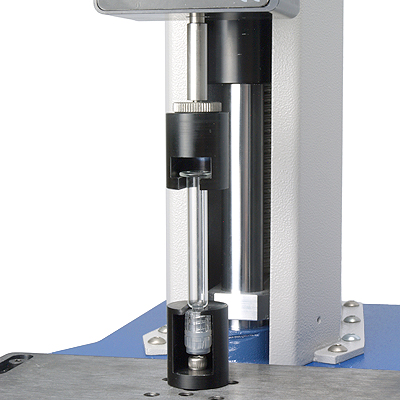

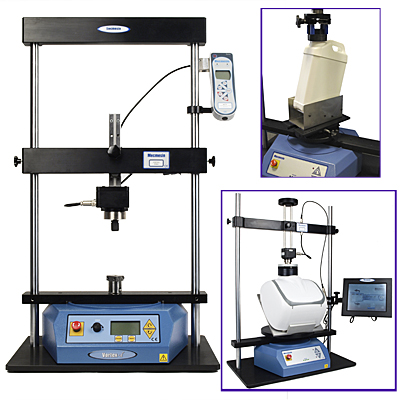

Medical device manufacturers operate in one of the world’s most competitive and highly-regulated industries, where success and lives hinge on compliance to standards, time-to-market and results traceability (raw data retention). A robust audit trail is important for the OEM if the customer has a product problem in the future. Syringes must deliver and extract fluids in a smooth, controlled manner; a plunger that is too easy or hard to actuate, or that stalls or judders on depression will not perform reliably during injection or aspiration. The testing of manually operated sterile single-use hypodermic syringes for glide (in both aspiration and expression strokes) force is essential under industry standards. These forces will be determined by a range of variables, the size of the syringe/needle aperture, the ‘fit’ of the plunger within the syringe barrel, the materials used and, in service, the density of the tissue substrate and the viscosity of the liquid. The syringe must be developed with the optimum balance of these variables to assure consistency and usability. Typically, a constant rate of plunger depression (and withdrawal) of the order of 100 mm/min is indicated for this test. A compression tester should be employed that deals with security – a log on for operator identification - and software to accurately control the plunger displacement and record the data. A fixture to grasp the finger flange for tension and compression strokes, with adjustability for syringe sizes, may also be required.

Mecmesin Systems: Touch screen test systems, Emperor™ (Force)

Video: Syringe plunger actuation force

Standard: ISO 7886-1

The 6% conical taper Luer connector for syringes, needles and other medical devices can be push/pull taper only, or a taper and screw (“Luer lock”) fitting. Light assembly and disassembly torque to turn is required to seal so that even a child could use successfully, whilst remaining leak-proof. However, a successful seal at low torque improves at higher torque. In the case of Luer locks, torque assessment should be performed on a low-level torque testing system, with a motorized base plate and a low capacity (e.g. 1.5 Nm) torque transducer. The most common test involves tightening the Luer lock connection between a needle housing and a fluid-filled syringe to a pre-determined torque, and visually inspecting the joint for leakage. Universal gripping pegs may be used to hold the sample in place, although customized fixtures ensure greater accuracy and repeatability – keeping the sample concentric with the torque axis is an important consideration. A floating fixture, or similar, to allow secure location into the needle attachment component should also be employed. For in-house quality standards compliance, a semi-automated syringe tester using a touch-screen controlled torque testing system which can be programmed with acceptable limits for the syringe is recommended. The operator is presented with a colour coded pass/fail result for easy identification of the sample status.

Mecmesin Systems: Touch screen torque test systems, Emperor™ (Torque)

Video: Semi-automated syringe tester

White Paper: An Examination Of Needle And Syringe Force Testing

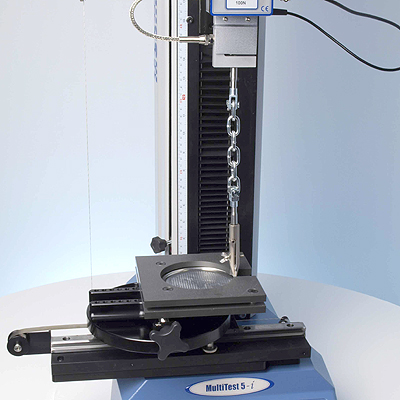

The foil lid of blister packaging must allow separation in normal use by means of peeling the flexible layer from the formed container without tearing. The adhesive strength of the bond should facilitate this ease of opening and also guarantee the reliable sealing of the product within, which may be a liquid or gel with hygiene or sterility requirements in the pharmaceutical or food industries. Peel testing of these packages to external or internal standards has several challenges in order to replicate the actual manner in which the elements are separated in service and to repeatably focus the test of the adhesive characteristics of the bond itself. Maintaining the peel angle (initiated at 135 degrees) to within the desired specification may require the design of a custom fixture – a jointed chain can effectively replicate the manner in which a consumer will apply the tension to the lid. Grasping of the corner of the foil in a manner akin to human fingers will require suitably sized pinch grips. In order to focus the test on the bonding around the blister perimeter, the surface needs to be kept flat and in a non-deformed condition, to avoid introducing inaccuracies into the process and ensure repeatability. The use of a pneumatically-activated vacuum fixture specifically moulded to the blister profile is the reliable solution.

Mecmesin Systems: Touch screen force test systems, pinch grip

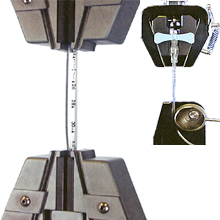

The testing of adhesive tapes and coatings present challenges for the product manufacturer in any industry, as the procedure itself must test the performance of a thin layer of bonding and often handle a flexible adherend on at least one surface. Peel resistance is the primary type of test for these bonded products and both international industry standards and internal checks demand the secure location of the sample whilst also allowing resistance-free relative movement between the adherends to enable the relevant layer to peel without obstruction. A manufacturer of filters for customers in the tobacco industry has varying specifications for the brands it supplies and the health and safety implications of such products (they are in contact with the mouth) also means that legislation is constantly evolving, with impact upon the manufacturing process and raw materials. The delicacy of the components (cellulose acetate filter and paper coating) requires consideration in the design of test fixtures to quality assure the peel resistance. Four locating dowels mounted on light needle roller bearings ensure that the rotation of the sample is as friction-free as possible and able to float within the fixture, as the paper coating is pulled vertically at a constant rate to unwrap. The locating fixture itself is securely anchored to a modified anvil base plate. This internal test is closely related to the 90 degree peel, floating roller, climbing drum and German peel wheel tests, but has been developed to meet the unique situation of the cigarette in service. Software captures the peak force, or any other measurable attribute that the manufacturer or customer needs.

Mecmesin Systems: Computer-controlled force test systems

Improving the reliability of the yield of foodstuffs is of global concern to the agricultural industry. An increase in the variety of specific dietary requirements for an individual’s health choice and the need to cater for population growth mean that achieving high quality yield from crops is essential. One reason for crop failure is lodging or permanent displacement, where the individual plant bends to lie flat on the ground – or displaced enough through flexure from upright to be unable to be harvested in an efficient manner – causing any number of remedial actions at cost to the crop-producer. Whether the lodging is caused by wind, soil composition or other factors, the application of a scientific approach to the forces and torques which the actual plant can resist will improve the understanding and ultimately success rate of the yield. The shots are considered cantilevers, anchored at their roots into the soil. The ability to test the crop bend flexure in the field necessitates not only a scientifically designed test, but also custom-engineered equipment which is simple, reliable, robust and portable. A tool to apply a controlled torque and an accurate digital gauge to measure of fundamental mechanical attributes of the shoots: centre of gravity, balance point and gravitational moment will allow food producers to evaluate the effects of changes to the processes which can influence the plants themselves, from nutrition to genetics.

Mecmesin Systems: Static torque screwdriver, digital force and torque indicator

Case Study: Testing roots and shoots

A manufacturer of performance sports equipment, which is then sold on to customers in its own supply chain for final production design, must ensure that the fundamental product meets the highest quality standards. The polyurethane (PU, PUR) foam used for the manufacture of surfboard blanks is subsequently coated for various design reasons, but the fundamental strength characteristics should assure safe, reliable performance for this lightweight material. For the manufacturer to provide a guarantee of product performance to its customers and to also obtain objective judgements regarding the raw materials received from its own suppliers, a repeatable, representative strength test is needed. The localised forces exerted by the surfer on the upper side of the board and the more generalised forces from the wave on the lower surface result in 3-point flexure being the relevant test type to measure the rigidity and strength of the product. A 3-point bend jig, with adjustable lower support arms and the capability of friction-free force application can be used to accurately apply the flexure symmetrically across the sample. A constant axial compressive load is produced by means of a constant speed application of the blade by the motorised test stand. Connection of a digital gauge and graphical output from software enables the manufacturer to compare the peak load data for different board constructions.

Mecmesin Systems: Motorised test stand, gauge and software combination, 3-point bend fixture

Case Study: Surfboard 3-point bend test

The ROPP design of glass bottle cap is a popular solution for drinks manufacturers and brewers, featuring pilfer-proof indication by means of a tamper evident ring. The metal closure has a liner to ensure hermetic sealing to prevent leakage and preserve flavour, freshness and gas content of sparkling varieties. To quality assure the capping process is providing an application force and torque to achieve these objectives, whilst still achieving in-specification removal torque, a portable digital torque test instrument may be used at the point of production. An adjustable saddle plate and fixing pegs will allow a variety of shapes of bottle to be quickly accommodated and tested. For additional convenience, repeatability, and ease-of-use – important considerations in rapid through-put automated manufacturing environments – is an audible pass/fail indicator and the ability to connect the instrument to results analysis software and transfer stored data. The closure torque values typical for this solution mean that the simple application of removal torque by hand is possible, rotating the closure through the breakaway and bridge torque points, providing an efficient and representative test standard.

Mecmesin Systems: Tornado digital torque instrument, large saddle plate, adjustable fixing pegs

Case Study: ROPP bottle cap removal torque test

The extraction of the cork closure from a glass bottle of Champagne, or similarly sealed sparkling wine, must be able to be performed easily enough to successfully release the beverage for consumption. As with all drinks containers, the stopper has to provide effective sealing to ensure the product remains in perfect condition, free from leakage (even after horizontal storage) and as freshly fizzy as when originally bottled. Additionally, the natural cork material should remain intact under the closure's removal torque required. A prime objective of a testing system to allow repeatable measurement of the peak release torque, suitable for a governing body responsible for evaluating the consistent quality of all products, is to reduce wastage in testing the full bottles of wine. A reliable quality assurance process needs several functional requirements. The ability to securely hold varying bottle sizes – magnum, standard (75cl) and demi – requires a design of fixture with quickly interchangeable jaws, able to grasp different radii and locate glass samples without slippage. Pneumatic operation of the clamps further enhances the efficiency of the method. The clamping of the cork within the upper fixture, must similarly be secure plus allow the cutting of the muselet wire prior to operating the test. The motorised system is geared to rotate the upper fixture as the bottle is simultaneously lowered at a constant speed. This complete, flexible, automated solution includes a safety enclosure to guard against spillage.

Mecmesin Systems: CombiCork-d, Advanced Force and Torque Indicator

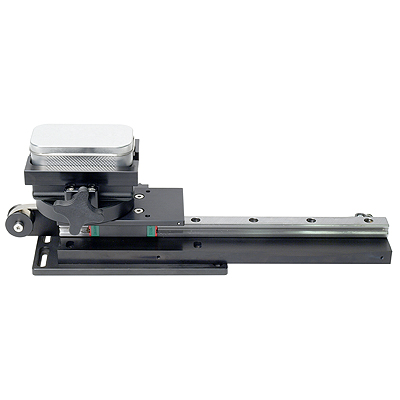

Mass production of goods often involves the transfer of items through the machines and transport mechanisms of the manufacturing process. Efficiency can be lost if the items misfeed or otherwise fail to move smoothly between operations. Consumer packaging used in the packing and shipping of products is affected by the frictional properties between the packaging material itself and the surfaces upon which it needs to slide. A specialist test solution to accurately measure the forces required to overcome the static and kinetic friction between the two surfaces enables the production organisation to evaluate different materials. Furthermore, this information then affords optimisation of machinery settings. A computer-controlled solution would involve a flat table upon which to locate the material sample, across which a block (‘sled’) of known mass is pulled by the test program. The force needed to initiate the movement is a function of the static friction (‘stiction’), the calculation of the average force to then maintain movement indicates the kinetic friction. The graphical output can also give an indication of the material’s propensity to cause judder or other undesirable characteristics.

Mecmesin Systems: Computer-controlled force test system, test hook

Case Study: Coefficient of Friction Test

To maximise the service life and optimise the functionality of electrical systems – generators, motors, etc. – the electrical insulation component is vital. Often in the form of tapes, comprised of combinations or layering of polyester, mica (or mica paper) and glass fibre, these elements must have a certain degree of flexibility in their mechanical properties and prevent electric flashover and conduct away any dissipated heat. International electrical standards define specific tests to measure the stiffness of insulating materials based on mica. To meet these standards a purpose-built tape bend fixture will be required which performs a 3-point bend along the axis of the tape test specimen. The insulation film, mica uppermost (if layered, with the faced material uppermost) is placed symmetrically over a 5mm wide slot in the support platform and a tapered penetration bar is lowered until a peak resistance force is achieved. The stiffness is defined as a rigidity calculation – the ratio of maximum flexural load to sample length. The test for an individual product type is performed on 5 representative samples and the mean, maximum and maximum calculated rigidity values are reported for compliance, in addition to the temperature conditions (required to be 23 °C ± 2 K) and humidity.

Mecmesin Systems: MultiTest console-controlled force test system

Standard: IEC 60371-2

Electronic communication devices are designed to be comfortable and ergonomically efficient in their usage, especially in environments where the product may be worn for extended periods – for example by company contact centre agents. The microphone arm of hands-free headsets may be designed to deploy and stow as needed, and as such must do so in a precise manner with positive engagement, yet operate with a light enough torque to turn to not require excessive effort in prolonged, repeated use. The implementation of a computer-controlled torque test system provides a manufacturer’s Research and Development department with the flexibility to create a suite of test programs for an extended product range. Custom fixtures to attach to the torque cell may be built to accommodate a variety of designs (over or on-ear, wireless, Bluetooth) and sizes (mini, ear-clip or full-size over the head) to swing the component through its complete arc. An adjustable lower table fixture also must securely locate the body of the headset. Interchangeable torque cells will allow accurate measurement for various models – production or prototype designs. The software should be programmed to report the salient characteristics of the torque curve – peaks to initiate the rotation and locate the arm into the home position as well as the peak and average effort in the main stage of the actual rotation (running torque).

Mecmesin Systems: Conputer-controlled torque test systems, Emperor™ (Torque)

Case Study: Headset Microphone Joint Torque

The action of brush bristles in any in-service situation is quite a complex system. Many forces are applied, often in multiple directions and the action of frictional forces also has an impact on the durability of the product. In addition the retention of the bristles (filament shedding performance) is an important consideration. A simple manual toothbrush is subjected to these conditions, as well as industry test methods applicable to cosmetics and personal health – specifically dental equipment standards. A versatile and complete testing solution should be able to perform the bristle stiffness test, in which the complete brush tufted area is rubbed against a metal grid at constant speed – subjecting the bristles to a cantilever bend force. The forces recorded then categorise the toothbrush into consumer categories from soft, through medium, to hard. Shedding performance can be measured by pull-of/pull-out for individual filaments or a ‘tuft’ of bristles with a surgical clamp and a pin chuck fixture, respectively. Location of the toothbrush head should be secure in order to eliminate flexure in the plastic (polypropylene) housing itself. A robust console-operated system would allow testing in a mass manufacturing environment, with simple operation for production staff, giving the confidence to meet stringent quality standards.

Mecmesin Systems: MultiTest console-controlled force test system

Case Study: Toothbrush Stiffness Tester

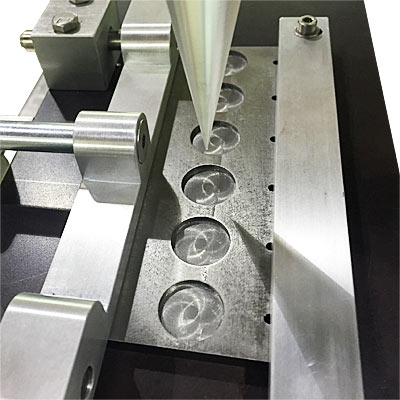

The 6% taper Luer lock-type of fitting (screw or lug) for syringes, needles and other medical devices has the primary purpose of ensuring a leak-free connection in delivering fluids. For systems using semi-rigid materials (e.g. plastics), the relevant standards require a specific metal conical reference fitting to be used, either male or female, to test both parts of the connector, ensuring control over dimensions and tolerances. A test system which is able to accurately apply a top-load axial force is required (27.5 N), with the simultaneous application of a very small torque value of 0.12 N.m. There are additional considerations in the design of an automated, purpose-built, test system for these standards, which are validating that the fastening torque is satisfactory to achieve the seal. Namely, the provision to supply the fluid to the Luer component and to a stipulated pressure for the liquid leakage standard, or to draw fluid into a syringe to a percentage of its capacity for the air leakage during aspiration (filling) test. The testing for liquid leakage requires the application of an effective internal water pressure of between 300 kPa and 330 kPa once assembled to the reference fitting. Visible inspection for leakage is then performed – falling drop of liquid or continued formation of air bubbles.

Mecmesin Systems: Helixa precision torque test systems, Mecmesin purpose-built test systems

Applicable Standards: ISO 594-2, BS EN 1707, BS EN 20594-1 ISO 80369

White Paper: An Examination Of Needle And Syringe Force Testing

The 6% (Luer) lock-type of conical tapered connector, used in fluid delivery systems in the medical field, must ensure leak-free performance at all times. Whether in hand-held syringes or other devices, such as infusion pumps supplying nutrients or medication, the seal must remain intact so as to provide the exact dosage – and this unscrewing torque test evaluates the device’s resistance to coming apart. The testing standard for semi-rigid versions of Luer components requires precise assembly of the connector under inspection (male or female) to a metal reference fitting prior to performing the specific functional test - 27.5 N top-load and 0.12 N.m torque. Due to the light loading values required for these devices, a precision test stand is needed. The unscrewing torque test requires that a very small torque (0.02 +0/-0.002 N.m) is applied and then held for a minimum amount of time. Precise alignment is essential to ensure than no other forces occur along any other axis, and the test stand must be able to provide this level of control. The Luer connector must remain attached to the reference fitting to comply.

Mecmesin Systems: Helixa precision torque test systems

Applicable Standards: ISO 594-2, BS EN 1707, BS EN 20594-1 ISO 80369

White Paper: An Examination Of Needle And Syringe Force Testing

Medical device connectors with a Luer lock (6% taper), which are manufactured from semi-rigid materials, are subject to an ease of assembly test under industry standards, which stipulates precise application force and torque values. Rigid devices need only be assembled to the definition of “secure”. To assemble the Luer lock to the metal reference fitting (27.5 N top-load and 0.12 N.m torque), connectors made of plastic require a test stand which is then capable of simultaneously imparting an axial force, not exceeding 20N, on the screw fitting together with a small torque, not exceeding 0.08 N.m. The connector should completely assemble under these loads to pass this specific fastening torque test.

Mecmesin Systems: Helixa precision torque test systems, Mecmesin purpose-built test systems

Applicable Standards: ISO 594-2, BS EN 1707, BS EN 20594-1 ISO 80369

White Paper: An Examination Of Needle And Syringe Force Testing

Connector components of a fluid delivery system must be able to be assembled quickly and reliably in the medical and healthcare environment. The Luer lock solution is threaded (or has a lug) and more secure than the Luer slip-type and so must be able to be easily screwed together to provide a leak-free seal, that will not be compromised by under or over tightening – and verified by fastening torque testing. The relevant standard refers to the latter condition as overriding, and repeatable testing to this standard requires the precise application of a 0.15 N.m torque to the component in the tightening direction. This torque must be held constant for 5 seconds and the test stand program must be able to facilitate this condition. As with the related Luer lock tests, the sample must first be assembled to the reference fitting by a simultaneous maximum axial force of 27.5 N and a light maximum torque of 0.12 N.m torque prior to the overriding torque application

Mecmesin Systems: Helixa precision torque test systems

Applicable Standards: ISO 594-2, BS EN 1707, BS EN 20594-1 ISO 80369

White Paper: An Examination Of Needle And Syringe Force Testing

The performance of Luer locks (6% conical taper connectors with a screw thread or lug method of assembly) must be maintained throughout the duration of their use in the fluid delivery system. These medical devices are designed to ensure a leak-free condition, whilst being quick and easy to remove and replace as demanded by the patient’s treatment program. In addition to tests focusing on the assembly of the connector, industry standards also prescribe tests to meet durability demands while connected at a reference fastening torque. This particular requirement needs a test stand capable of applying both a torque (0.12 N.m) and an axial force (27.5 N) held for 5 seconds, to assemble the Luer lock initially. To complete the stressing of the components, a constant temperature of 20 ± 5 °C (27 ± 5 °C in tropical climates) is maintained for a period of 48 ± 1 h. The components should be free from cracking at the completion of the test. Additional consideration should be given for specific environmental conditions applicable to the device’s use – which may include contact with chemicals in addition to elevated temperatures.

Mecmesin Systems: Helixa precision torque test systems

Applicable Standards: ISO 594-2, BS EN 1707, BS EN 20594-1 ISO 80369

White Paper: An Examination Of Needle And Syringe Force Testing

The 6% taper Luer lock-type of connector has widespread use for hypodermic syringes, needles and with certain other apparatus for medical implementations, such as transfusion equipment, for the delivery of fluids. For systems using semi-rigid materials (e.g. plastics), the relevant standards require a specific metal reference conical fitting to be used, either male or female, to test both parts of the connector. The testing of separation (pull-off) compliance requires that the element of the connector under test remains attached to the reference fitting. The Luer component is first applied to the reference fitting by a maximum axial force in conjunction with a precise, small value, maximum torque (27.5 N top-load and 0.12 N.m torque). Once located, the test must apply another strictly axial force away from the test fixture at a constant rate of 10 N/s up to a maximum value of 35 N and for a minimum time of 10 s, in order to evaluate the pass or fail condition for the pull-off test. The subsequent part of the method may require a different test stand to complete the full quality assurance process to acceptable accuracy, due to the significantly different force values to that required to locate the fitting initially. A constant rate of traverse system can achieve the necessary force application rate by prior testing to equate the displacement rate for the sample type under inspection.

Mecmesin Systems: Helixa precision torque test systems and MultiTest motorised test system

Applicable Standards: ISO 594-2, BS EN 1707, BS EN 20594-1 ISO 80369

White Paper: An Examination Of Needle And Syringe Force Testing

The effective sealing of food items with plastic film relies on a degree of flexibility and strain within the film in order to enclose and achieve air-tight packaging. A two layer construction, with the outer layer bearing the printed product information, may be quality verified for integrity by a tensile strength test. The packaging material should exhibit a degree of elasticity, but still meet expected levels of tensile strength before breakage. The challenge to securely hold the sample without slipping or damage the thin material is achieved with spring-loaded roller grips. A motorised force test stand with a digital force gauge and software is a repeatable solution for measuring the peak force to break apart the plastic layers under constant speed loading. This compact system is ideal for the quality control or research laboratory.

Mecmesin Systems: M500E motorised test stand with gauge and software, spring-loaded roller grip

Case Study: Plastic Film Tension Test

The components in rotating machine tools which are designed to work on materials, need to remain securely located in order to accurately wear the target surface. Small abrasive disks used in the dental industry (to shape implants), should be tested for integrity by evaluating their resistance to an applied torque to turn created between the implant surface and the driving spindle of the tool. Using a custom-designed adaptor, the abrasive disks may be tested to check that they do not become loose on their central hub when in service. Should the breakaway torque be less than required standards, the supplied batch can be rejected. The disks are marked clearly prior to being loaded onto the adaptor to show any subsequent rotation. The adaptor securely clamps the abrasion surface itself and a custom probe is lowered into the spindle bore. The software program rotates the locked probe 90 degrees clockwise and 180 degrees anti-clockwise. If the disk has rotated in the hub, then the component fails. Slippage around the spindle or rotation against the fixing (much less likely) would show no indicated disk rotation. The torque is measured and the test results graphically displayed to further quantify the level of discrepancy between specification and achieved peak torque.

Mecmesin Systems: Vortex torque test systems, EmperorTM (Torque)

Video: Dental abrasive disk testing

Electrical lighting displays which are erected on buildings in public areas, such as seasonal illuminations, are subjected not only to specific electrical standards, but also legislation surrounding their installation, operation and removal. The fastening hooks/eyelets securing the cables to buildings or other structures must resist tension forces designed to test pull-out from their anchoring and tensile strength of the attachment or its bolts. Due to the location of these anchorage points – usually in high-up or relatively inaccessible spots – a test system with the emphasis on lightness and portability is required. The ability to also store multiple readings within the gauge’s on-board memory, ensuring traceability of the measured peak force values back to individual fastenings, should also be a requirement. The data may be analysed offline to evaluate the entire electrical system’s integrity once the gauge has collected the information. For additional safety consideration for the operator, a handle for the gauge should be employed.

Mecmesin Systems: Digital force gauge, manual handling kit

Case Study: Festive Lighting

The medical devices and associated services industries are subject to strict quality standards testing. The complete life-cycle of the equipment is covered, including the safe disposal of used, contaminated items. Manufacturers of products involved with the safe discarding of medical devices with needles (‘sharps’) must conform to British Standards to provide proof against puncture by clinical waste materials. These sharps bins will be handled by staff from several organisations in the chain, not all specifically trained in medical practices, thus safety must be assured against the puncture of the container material by the waste. A puncture resistance testing process should allow a variety of sample types – specifically material thickness – to be securely located by means of an adjustable base fixture that has sufficient clearance to drive the needle point a certain distance through the surface of the standard diameter sample. An extension rod to fit the syringe hub is required for the crosshead fixture. Measurement of the peak force applied to create a breach can be achieved with computer controlled test programming and run from a touch screen console with each unique test associated with a sample type.

Mecmesin Systems: MultiTest touch-screen test system

The seals on tamper-proof (or tamper-evident) closures are designed resist an unscrewing torque up to a specific value. The tamper-evident band on the cap should remain intact for safety reasons, until it is positively breached and the bottle opened for intended purpose. Testing of this bridge torque for a range of products is needed to optimise the balance between ease of opening and security. Testing the cap designs in isolation from the bottles themselves in a product design environment can be achieved through the use of bespoke mandrels in the standard manufactured sizes produced by the supplier. These fixtures ensure a repeatable grasp of the cap and a precise hold of the tamper-evident ring for confident back-to-back testing of design variants. A digital torque indicator gauge, with on-board memory - for storage of the peak torque - and data transfer capability allows the collection of results for analysis.

Mecmesin Systems: Advanced Force and Torque Indicator, torque mandrels

Case Study: Torque Tester for Dedicated Caps

All sterile medical devices require validation of their packaging. The flexible sterile barrier must be shown to be effective throughout the product's claimed shelf-life. The integrity of seals and welds is of critical importance and the testing of the bonding strength of these seals is often performed by peel test, the flexible material on both layers necessitating either 180 degree or T-peel. These tests are also relevant to package openability and evaluating the manufacturing processes’ ability to produce consistent seals and the peak force and/or the average force to open the seal may be relevant. Inspection after the test may reveal either the adhesive has failed to adhere to a substrate (adhesive failure), in which case the bond strength has been measured. Conversely if the bond has failed internally (cohesive failure), or the packaging material has delaminated, torn or failed in another manner, then the test has exposed deficiency in the overall specification of the seal. Usually a representative strip is cut across the seal of a standard width and a T-peel is performed. An important consideration in the fixture design may be to mitigate against bending – by supporting the unpeeled portion of the sample at 90 degrees to the peel direction.

Mecmesin Systems: MultiTest console-controlled force test system, lightweight double-action vice grips

Standards: ASTM F-88, EN 868-5

The performance, durability and safety conformance of clothing must reflect the multitude of styles and materials mix plus functional and decorative additions. These various embellishments: buttons, ribbons, bows, sequins, diamante and other fastenings that have been attached to textiles need to be checked that they have been safely affixed so they will not become choking hazards for infants, for example. The necessary test-to-failure (TTF) indicated by the standards – a code of practice for the design and manufacture of children's clothing to promote mechanical safety – involves pulling the feature until it detaches. The method tests the pull-off/pull-out and tensile strength of the product and also recording the displacement of the crosshead will give a measure of the elongation at break. A selection of grips may be required for securely grasping the decoration – with hooks or slots – depending on the design.

Mecmesin Systems: MultiTest console-controlled force test system, digital force gauge, test hook, popper-cam base

Case Study: Diamante Pull-off Test, Bow Pull-off Test, Button Pull-off Test, Press-Stud Popper Pull-Off Test

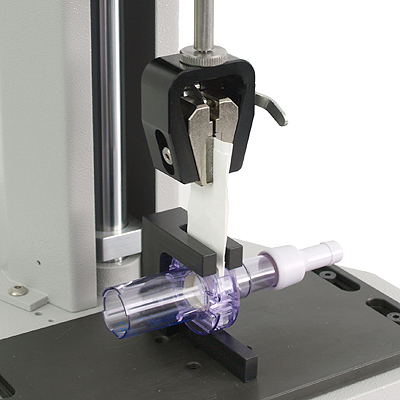

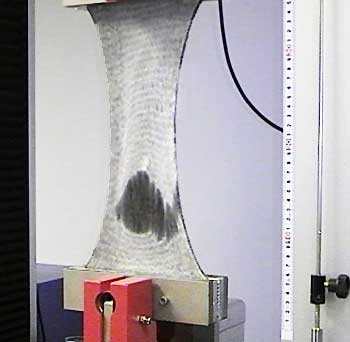

Plastic extruded medical tubing is an essential health care product for the delivery of blood, nutrients and gases to the patient, and for the execution of minimally invasive surgical procedures. The tubes, for example catheters, may also be connected to other medical apparatus such as Luer devices, butterfly valves and pipe junctions. A manufacturer of these products must meet strict regulatory compliance in conjunction with optimising the functional design - for efficiency plus patient comfort and safety - while also meeting production costs. An in-house quality testing regime should consider the in-service forces exerted on the individual components and the complete system of which the tubing will be a part. The tubing itself can be tested for tensile strength and elongation behaviour with a force test stand and a selection of appropriate grips and fixtures pertinent to the product’s performance requirements in situ. A computer-controlled system is perfect for an OEM’s research and development lab, allowing the collection of results and bespoke test programs applicable to a range of products. The challenges to reduce the wall thickness to minimise trauma and maximise the lumen bore to maintain flow capacity can be met with structured, repeatable quality testing processes.

Mecmesin Systems: MultiTest computer-controlled force test system, 5 kN wedge grips, bollard grips

White Paper: Force Testing Medical Tubing

The tamper-evident caps on bottles are designed to resist breaching through unscrewing torque and/or pull-off force until opened for intended purpose. Correct opening requires unscrewing, with the option of resealing again for consumer convenience. The integrity of the tamper ring may also be tested against other removal forces experienced in transit or mishandling that would compromise the intended functionality. A peak force test to pull the cap (without rotation) until the tamper-proof band breaks away may be used to evaluate the design with respect to in-house standards. A console-operated system is convenient for production environments, with simple touch-screen operation to run a programmed test procedure. To augment throughput efficiency a custom-built fixture which allows one sample to be tested whilst another is loaded may be implemented. The cap is pushed over the fixture collar, manufactured to replicate the exact profile of the bottle neck. A concentrically-mounted compression probe is driven down through the sleeve, engaging inside the cap and compression-loading it until one or more of the tamper ring’s bridges fail. The recorded peak force reflects the overall tensile strength of the bridges and may be used to compare designs or supplier batches.

Mecmesin Systems: MultiTest console-controlled force test system, Emperor™ (Force)

The bung used to stopper a beverage bottle must provide a leak-free seal to protect and preserve the liquid contents, whilst still allowing an ease-of-opening to access the contents. The removal process may involve a combination of pulling force and some rotational torque in practice, however to implement a repeatable quality assurance test, a standard method must employed. The axial force of extraction gives a consistent indication across different samples and provides greater simplicity of test procedure than mixing the pull-off/pull-out force and torque elements. An adjustable clamp to grip the glass bottle and a quick change fixture enable the versatility to test different categories of container from standard to magnum, as necessary. A chain link assembly connected to a suitable cork screw is used to locate into the plug material and apply the tensile load via the crosshead. Software control of the test stand and the ability to clearly indicate a pass or fail condition complete this system for reliable and accurate closure testing.

Mecmesin Systems: Force test systems, Emperor™ (Force)

Videos: Combi Cork Extraction Tester

The butt joint is inherently the weakest category of joint between two components, especially if a reinforced type is not used. The tensile strength of the connection is wholly dependent upon the bonding system, whether this is in contact with raw materials or the adherend is the coating on the surface(s). This type of joint has applications in many industries, from wood-working to large engineering systems. With metal components, welding is an option, however the advantage of a glue-based system is that it allows the full surface area of the butted faces to contribute to the strength. The overall failure of the joint under pull-off loading may be cohesive (where the glue suffers a lack of integrity) or adhesive failure at the glue/coating or coating/material connection. The latter is indicative of deficiency in the coating process, or evidence of the bonding agent having a detrimental effect on the coating. A butt joint test system must be capable of exerting enough force to break the butt joint apart, perfect axial alignment and deal with the possibility of a sudden catastrophic failure of the joint.

Mecmesin Systems: MultiTest computer-controlled 50 kN machine

Case Study: High Performance Plasma Coatings

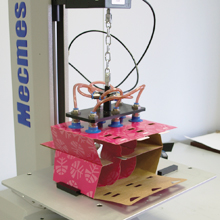

Boxes for the consumer and transit packaging industries must be as light as possible whilst still retaining a robustness to contain and protect their contents and also have the strength to stand up to shipping, handling and stacking requirements in service. The use of corrugation adds rigidity to paper and card packaging materials, which are tested in compression with several crush testing / top-load standards, namely the box crush test (BCT) and the related edge crush test (ECT) and stacking crush tests. Suppliers may also require modified tests to suit specific customer’s needs, as transit packaging particularly can undergo a variety of loading during its journey. The international industry quality assurance procedures for the box compression test may require self-levelling compression plate(s) in order to follow the pattern of failure, or some standards stipulate only the upper must be spherically pivoted to meet this requirement. Other standards indicate rigid compression plates when loading opposite sides (or corners) of the box. The BCT test loads the box at a constant rate to a nominal compressive load, or until the container collapses. In-house testing may use custom fixtures to load the box for unique crush situations such as edge to opposite edge.

Mecmesin Systems: Force test systems

Standards: ISO 12048, BS EN 22872:1993, ISO 2872:1985

Moving components in transportation systems are critical in the safety of the passengers using the systems. Doors, windows, shutters and other sub-systems that open and close are all potential sources of accident or injury through misuse or potential malfunction. A public transport system, such as a train or similar transit vehicle with multiple carriages and sliding flush-fitting entry/exit doors would require a portable and simple, but representative test procedure to measure the maximum pinch force of all the doors. An effective solution involves a custom, cantilever activated arrangement which can be placed safely (for the operator) between the doors and loads the digital force gauge. The selected gauge, dependent upon features and functionality, may be set to immediately register a pass/fail result and audio warning.

Mecmesin Systems: Compact digital force gauage (CFG+), Advanced Force Gauge (AFG)

Case Study: Train Door Closing

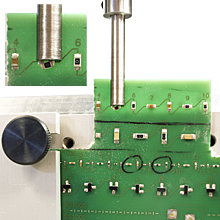

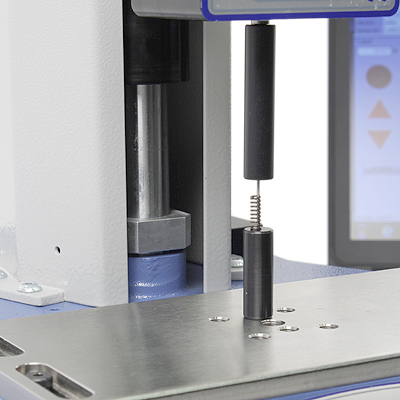

The solder joints on a printed circuit board (PCB) are small and potentially delicate but must be able to withstand handling during the production process. Hand soldering production methods for such small elements is highly skilled, requiring extensive manipulation of the components and thus risk of break-off. In addition to pull-out testing, the joints are subject to compressive shear loading. International test standards exist for this type of mechanical compressive shear stress. The loading probe must be exactly aligned with the surface of the substrate in order to create the shear plane and not place the joint under a bending load instead. To test multiple joints on an intricate board design, a custom system may be required to quickly align all of the joints with the fixture at the specified angle. Selecting a loadcell of appropriate range to record the best accuracy is also a consideration – these tests may need to measure forces of around 300 N.

Mecmesin Systems: MultiTest console-controlled force test system

Case Study: PCB Pull & Shear Test

Standard: IEC 62137

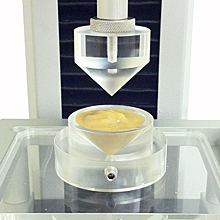

The mechanical properties of food and most cosmetics are more readily termed texture (also mouthfeel in the case of foodstuffs). The way these products are acted upon by forces determines the exact texture attribute, such as firmness, stickiness (adhesiveness) and spreadability. As such these items may be mechanically tested and the results used to quantifiably compare the effect of relevant production and manufacturing factors - for food: cooking time, relative mix of ingredients – on the consumer’s sensory perception of texture. The engineering concept of penetration resistance has direct correlation to the texture attribute of spreadability and the use of a cone-shaped penetration probe for a force test will allow repeatable and accurate texture analysis of a product judged by this quality. The matching container fixture for the sample is influential in the results as its degree of resistance to allowing the product to spread freely, but enables consistent comparative testing. Typically this fixture is shaped as an internal cone corresponding to the same dimensions (90 degree vertex angle) as the probe.

Mecmesin Systems: MultiTest force test systems, compression fixtures

Case Study: Margarine Spreadability

Sachets are convenient forms of packaging, as they are easy and quick to open and the ideal size for delivering small quantities or trial sizes of products. They are used as packaging for products from industries such as cosmetics and pharmaceuticals as well as food products such as condiments. Manufacturers need to ensure that their sachet packaging is strong enough to protect the contents through all stages of the manufacturing and distribution process, while remaining easy to open for the consumer. Tests carried out to ensure the integrity of the sachets include tear strength and tear resistance. These tests measure the strength of the material where it is intended to tear, e.g. along a seal or perforation and demonstrates the quality of the sachet to provide a barrier protecting the product from the external environment. Tear testing methods set standard conditions under which a material sample can be treated in a repeatable way.

Mecmesin Systems:Tear resistance test systems

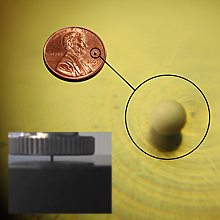

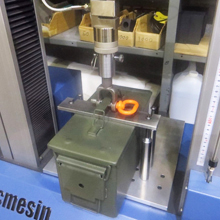

Crush strength is the peak compressive force required to take a sample to its [ultimate] compressive strength at which the onset of failure occurs. A single pellet crush test could be applicable to products such as pharmaceutical tablets (or similarly shaped confectionary), ceramics and industrial catalysts formed of solid material. The implications of failure in these industries is of varying degrees of impact – the industrial catalyst may result in plant shutdown and thus stringent testing is required. The physical shape of the pellet affects the exact test standard method: tablets and spheres being crushed by a different method to extrudates, granular or irregular shaped products. To accurately measure the mechanical properties of a single sphere under load, the use of self-levelling compression plates should be employed. A computer-controlled test stand will enable the first peak load to be captured as the sphere fractures and provision to avoid overloading of the loadcell as the fixture attempts to move beyond this point should be considered. Some examples of the spherical carrier are less than 1mm in diameter and control of the crosshead’s displacement is essential – either physically or by means of the software.

Mecmesin Systems: MultiTest computer-controlled force test system, self-levelling compression plates

Case Study: Alumina Sphere Crush Test

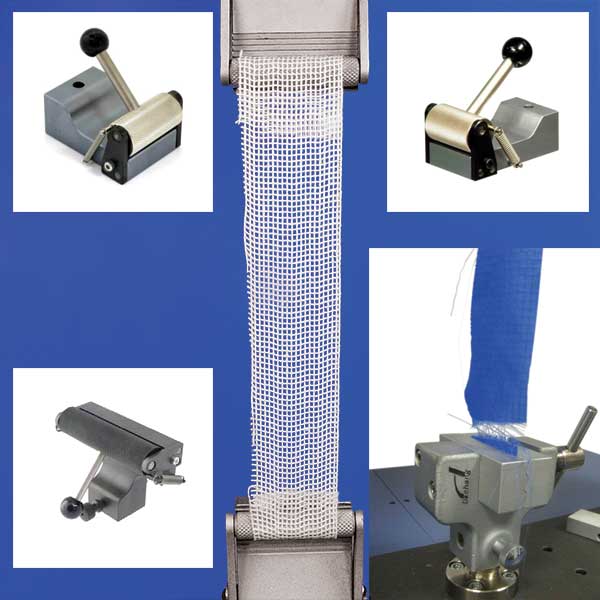

Zippers (zips, fly, fly fasteners) are used for the fastening together, or binding, of the edges of fabrics, textiles and other flexible materials. Usage in the clothing, furniture, outdoor pursuits and sporting industries is common. The fairly complex mechanical nature of the clasping mechanism, involving interlocking teeth and a hinged pull-tab, requires a set of tests to ensure the quality assurance of the complete assembly. The crosswise (ordinary zipper) strength per 2.5 cm of the chain, tests the peak load that the interlocked teeth can endure before being pulled apart laterally. The webbing at either side of a the chain is securely held with 25 mm wide grips and pulled apart at a constant 300 mm/min. The top stop (zip closed position) and the bottom stop (zip open position) are also tested. The top stop holding strength by holding the lower edge of the interlocked zipper and pulling the slider firmly in the closing direction. The bottom stop holding strength pulls each of the chains apart at right angles to the zipping direction in a manner similar to a trouser tear or T-peel test. The separating unit crosswise strength pulls the webbing apart at the point of the bottom stop with the zipper closed. The slider/tab configuration is also tested for its locking strength—resistance to sliding as a result of the chains being pulled apart—and, for relevant designs, the tab itself is tested for ultimate tensile strength when pulled away from its housing at 90 and 45 degrees. Custom-designed fixtures may be required for the complete suite of tests, primarily JIS-S3015 and ASTM D2061.

Mecmesin Systems: MultiTest universal testers, Customised force testing applications

The static and kinetic dry friction properties of contacting surfaces is extremely significant in the labelling, packaging, print and warehousing/shipping/moving industries. Surfaces which move over each other easily are preferred in the production of packaging materials—influential for machine settings to control rollers, feeders and grabbers. Higher forces to initiate relative movement are desired in shipping processes, where the minimising of slipping is fundamental for safety reasons. Testing must be performed to evaluate the surface roughness and the effects of surface coatings and inks, as the COF of such a system cannot be calculated—it must be measured experimentally. The key standards require a horizontal test plane and a sponge-covered sled of a specified weight to apply a known normal force between the surfaces. The accurate determination of static friction, which is calculated from the measurement of the first peak force value as the surfaces begin sliding, may require an elastic linkage between the crosshead and the sled to control the inertial impact. Once movement is underway, if dynamic friction is to be calculated, the critical threat to accuracy becomes stick-slip and fish-tailing. In this situation the option of an interchangeable, rigid link is necessary. The results of five valid tests are used in the calculation and extreme care must be taken not to contaminate the samples, which may also need to undergo conditioning at a standard temperature and humidity level.

Mecmesin Systems: FPT-H1 Horizontal Tester, Grips, fixtures and accessories

Standards: ASTM D1894, BS EN ISO 8295

Sheet materials are produced in volume and supplied in bulk, in formats suitable for machine handling. Surface characteristics change through coating, inking, abrasion, folding, creasing and perforation. Coefficient of friction is significant to throughput and different at each change of use. Pulp and paper manufacture may utilise large rolls for web offset presses, large flat sheet-fed formats, down to digital presses, copiers and office printers. When considering supply of paper and board, customers specify COF requirements, in relation to machine and cross directions, and other attributes such as rub and blocking, if relevant. Testing based on standard ISO 15359 requires dedicated hardware to measure the forces and hence accurately calculate the static and kinetic friction. A horizontal plane method is used, with a sled dimensioned so as to exert a specified normal pressure on the contact surface. Importantly, there must be the capability to the set-down, dwell time and lift of the sled so as to protect the test pieces from surface damage and ensure that the sliding is also expressly controlled. This test covers the measurement of the static and kinetic coefficients of friction, the dynamic value being measured after three slides, and the calculation requires six valid results to average. Similar test standards do not stipulate an elevating mechanism, thus the ability also test without this feature adds versatility.

Mecmesin Systems: FPT-H1 Horizontal Friction Tester, ASTM 15359 Friction testing accessories

Standard: ISO 15359, Tappi T549

The majority of syringes are single use, disposable and manually operated. Consistency in plunger operation (smooth, and to a correct pressure) is essential, so quality testing requires representative gripping of barrel and plunger, and complete repeatability. Glide force testing can include both filled and empty syringes.

Mecmesin designs custom fittings for syringes of all styles and sizes to ensure a secure grip of both parts without distortion and correctly aligned. For filled syringes, these include fluid collection. Testing becomes both quick and repeatable.

Bard Ltd services its biopsy injector units, which are driven by a powerful spring, primed and triggered by finger pressure. To verify spring strength in units returned for servicing, they must be held in such a way that the trigger can be compressed as in use by hand.

Mecmesin devised a custom fixture featuring a quick clamp and stirrup pull bracket. Placing units for programmed testing is quick, easy and reliable, increasing throughput and ensuring complete repeatability.

International standards (ASTM F2132, BS 7320) specify the puncture resistance of medical sharps containers. By using real sharps on samples taken from containers, on a programmable universal test stand, repeatable and reliable testing is possible.

Mecmesin designed and provided a Luer hub fitting extension to attach hypodermic needles of various designs to a loadcell, and a tubular sample holder to allow undistorted full penetration of the container wall sample.

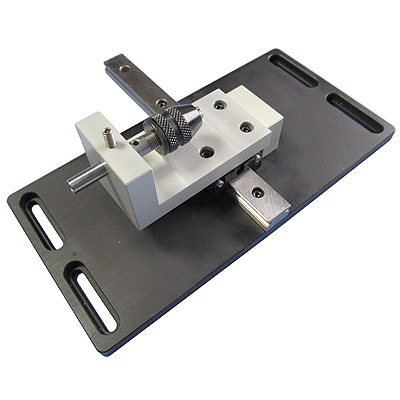

Adhesion quality in post-production packaging labels is a more accurate test than on basic materials, due to deposits on surfaces and from operating environments. Post-production packaging, such as small metal containers, can, however, be awkward to hold during test.

Our client needed to perform a 90 degree peel test on labels applied to small tin lids. Mecmesin designed a dedicated custom grip to hold the tin without distortion, on a moving table peel jig. This ensured correct alignment every time for repeatable testing.

Our client manufactures liquid bulk carriers with two-part plastic valve closures. The collar is welded to a plastic bag, and the valve closure is fixed onto it by a compression joint. These joints are tested for the force to connect the two, and to pull them apart. The force required can be as much as 25 kN.

Mecmesin designed a collar-retaining plate and flexibly-linked valve attachment to secure both parts without damage or distortion, on a twin-column test stand. The two parts are then pulled apart axially and uniformly, whilst allowing for uneven detachment.

The shear strength of soils and sands can be an expensive thing to test, since the shear force applied is perpendicular to the main compressive force, and universal testers operate in one direction. Our East European client required an affordable solution for more occasional testing.

Mecmesin designed a compression cell attached to an AFTI digital force indicator, that could be inserted into a Mecmesin twin column test stand to apply the shear force. This provided an accurate and cost-effective solution.

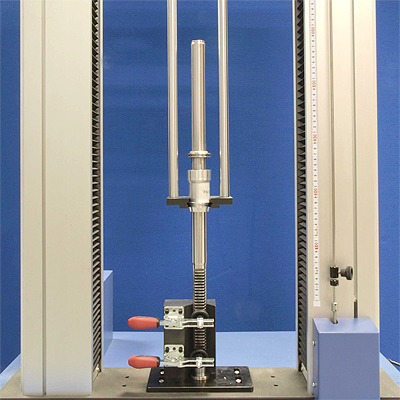

With a sensitive digital force gauge, such as the Mecmesin Advanced Force Gauge, a manually-operated test stand can be sufficient for small spring testing in compression or tension. For the lightest springs, very fine control is needed, and the standard gearing may be inadequate for fully-repeatable conditions.

With a sensitive digital force gauge, such as the Mecmesin Advanced Force Gauge, a manually-operated test stand can be sufficient for small spring testing in compression or tension. For the lightest springs, very fine control is needed, and the standard gearing may be inadequate for fully-repeatable conditions.

Gripping the base of a shaped glass bottle for a tensile test can present greater difficulties than for torque tests. Our client needed to pull a foil screw cap and tamper-evident sleeve from bottles of various sizes, without slipping at forces exceeding 1 kN. Barracuda grips are available for the cap, but the bottle required custom design.

Mecmesin designed adjustable V-jaws with rubber-edged finger grips that could interleave for smaller bottles yet be wide enough for larger ones. This provided the required grip under tension and axial alignment for the cap pull-off. Gripping samples securely becomes reliable and quick for improved throughput.

Propellants are avoided for many reasons in liquid and spray dispensers, with manual spring-loaded pumps used in their place. These are shaped for finger operation, and filled containers give a more reliable operational test. So how do you repeatedly test an awkward and messy pump dispenser?

Mecmesin met a client's needs with a custom designed bottle holder, and collection bin in stainless steel. This efficient solution ensured correct alignment, secure gripping under compression, and cleanliness.

Our client needed to test a number of small, lightweight springs under compression. To avoid buckling and sideways movement in the springs, a supporting spindle or spigot was required, to the dimensions of the springs under test.

Mecmesin designed and supplied compression probes with supporting pins, for operation on one of our regular MultiTest stands. These enabled rapid insertion and repeatable testing.

A pharmaceuticals company wanted to test the closure torque of a series of square-profile PET bottles. To minimise operator adjustment, they wanted to test all bottles at a constant height, using their Vortex-i torque tester.

Mecmesin responded by designing a set of nesting bottle holders along with a custom-moulded mandrel set. In this way each bottle could be axially aligned and presented at the right height under the torque head, for maximum test throughput.

Our client manufactures cosmetics brushes for all applications, and so has a very diverse set for bristle integrity testing. Gripping the shaped handles and bristle tips in a repeatable way demanded more than a single standard vice grip.

Mecmesin designed a system of overlapping plates with cutouts for each brush head profile, to gather and trap the bristles uniformly in a vice action, axially aligned under the loadcell. Barracuda grips hold the handles securely for reliable and accurate repeat testing.

Our client was testing the release torque of 20 mm long plastic catheter caps with irregular features to aid finger gripping. The test is performed by hand with a digital torque sensor, but achieving maximum grip and quick insertion required customisation.

Mecmesin designed a multi-finger mandrel to ensure maximum contact and exact axial alignment. This improved the accuracy of the test through repeatability and cost savings through efficiency in use.

Semi-rigid vacuum-formed packaging, sealed by film or foil, is tested by the 135 degree peel method, to represent hand-pulling. The difficulty for testing is always in mechanical holding of the container. Our client was testing food packaging of a particular design and required a custom solution.

Mecmesin designed and provided a fixture to hold the flexible container in a matched recess by vacuum, at 45 degrees to the test stand column, and to peel from a corner. The film lid was gripped and linked to the crosshead by a chain link to achieve a secure and repeatable test. Vacuum fixtures also allow for rapid throughput of samples for quick and efficient testing.

In addition to top-load carton crush testing, the compressive strength across opposite edges can be an important measurement. This represents a typical shelf and stacking situation where damage can occur from falling. Holding a carton for this test without slippage requires custom fixtures to achieve the correct length and angle of applied compression.

Mecmesin has met these requirement for a number of clients, with custom-designed V-profile compression bars. These ensure the same angle of testing, along the length of the carton to be compressed, for perfectly repeatable testing.

Plastic sachets with welded seams are frequently used for measured applications of liquids, creams and gels. A quick quality test for their integrity involves compression either to burst, or to resist a defined compressive force. This may require containment for spillage, but also for alignment. Our client was testing pharmaceutical sachets.

Mecmesin designed a sliding container, engaging under the test compression plate with ball catches for exact axial placement. This enabled quick exchange of test samples for maximum throughput and repeatability.

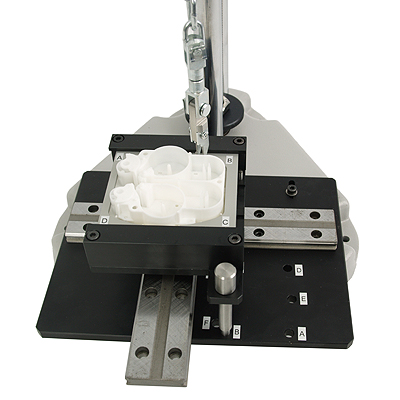

Our client manufactures glass syringes with compression-fit polycarbonate Luer lock adapters. Quality testing requires measurement of the torque required to rotate the adapter, to ensure it cannot come away under normal use of the Luer connection. The syringes come in various sizes, so a flexible range of grips was required.

Mecmesin met their needs with customised grips to hold the glass syringe barrel, and to grip the Luer adapter to turn it, with perfect axial alignment.

A packaging production company needed to test the maximum crease force in 90 degree folds in various materials. This required continuous accurate measurement by cantilever bend, through the folding movement.

Mecmesin designed a customised fixture to manually rotate the gripped card against a compression bar attached to one of our 100 N advanced digital force gauges. Clickstops at 45 and 90 degrees allowed the folding force to be recorded consistently at each angle for any material. Mounted on a manual test stand, this was a very cost-effective solution to their requirements.

Pull-off tests require careful support of the separating parts to avoid distortions affecting the connection, or breakage due to grips. Several of our clients have needed to test the pull-away force of flexible intravenous tubing from connectors.

Mecmesin has designed fixtures to support the connectors in axial alignment with the gripped tube, for fully repeatable testing and rapid positioning of samples. A simple and cost-saving solution to a common, but specific, test situation.

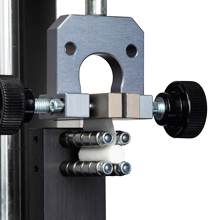

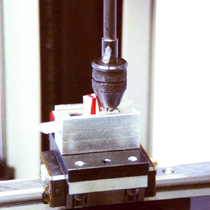

Familiar with three-point bending? Our client needed to fold insulating film strip along its length rather than end to end, so the usual flexure fixtures were not appropriate. Instead they needed a blade and slot fixture with sufficient width.

Mecmesin designed and manufactured a slotted anvil with graduations for accurate sample placement, and a polished chrome plated blade, for consistent insertion and fully repeatable testing.

Our client needed to test the peel quality of film lids on semi-rigid pre-filled syringe packs. Inconsistent peeling can result in accidental content spillage, so the force required at a standardised 135 degrees must be measured for a complete opening action. Holding semi-rigid packaging so that it does not deform, requires a custom application for each pack design.

Mecmesin designed and manufactured a vacuum holder for an exact fit to the pack, positioned at the required angle under an extended tensile test arm. The lid was then peeled back with a grip on a flexible chain link. An added advantage of vacuum fixturing is the speed and accuracy of sample changing for maximum throughput and efficiency.

Luer lock test standards frequently involve the application of a simultaneous and prescribed axial force. Our client required fastening and removal torque of caps from from syringes without this. Precision measurement of the torque to fasten and remove the cap needed a simple custom solution.

Two parts, to grip the syringe base and to engage the Luer lock cap, were designed by Mecmesin, and allowed rapid exchange of samples for accurate and repeatable testing at maximum efficiency.

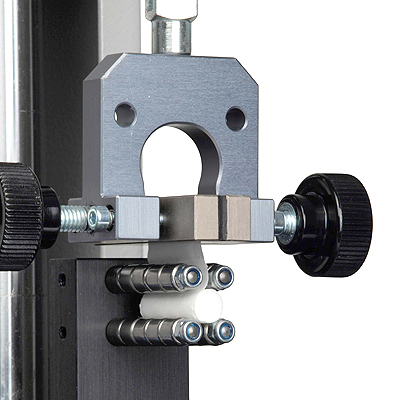

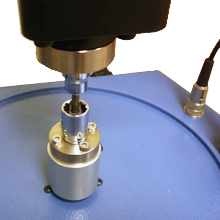

Floating roller peel jigs are available for security card lamination testing, but our client was testing the adhesion of the paper around cigarrette filters. To accommodate the small cylindrical shape required smaller and closer rollers, and a better sample loading design.

Mecmesin responded with customised fixtures for different sizes of filter, employing four roller bars instead of two. Loading samples for repeatable 90 degree peel testing is quick and easy, saving time and cost.

Torque testing of child-resistant bottle caps requires application of a simultaneous top load. Raising and lowering this repeatedly in a testing sequence is much easier, quicker and more secure when automated. Our client wanted to eliminate this manual effort by test operators.

Mecmesin supplied a pneumatic lift mechanism for the client's Vortex torque test stand, to lift the top-load weights and lower the torque head into place for each cap test. This makes batch testing quicker, more reliable, and less tiring for the operator to perform.

Test method standard BS ISO 4919 applies to the tuft withdrawal force of carpets. Our client tests artificial grass by the same method, and required custom fixtures for the coarser construction.

Mecmesin's solution was a quick-fit and release clamp plate for the matting, leaving an aperture for a forceps clamp suspended from the test loadcell. Testing is quick, easy and repeatable.

Endoscopic and laparoscopic surgical instruments are operated by axial and rotating adjustments in the handle, to perform precision movement in the head. One manufacturer asked us to provide test fixturing for the operating torque of a laparoscopic instrument in two controls, to splay and to flex the head.

Mecmesic adapted one of its Vortex-xt torque testers by extending its column height to accommodate the instrument length. By fixturing around the length, and gripping the twist controls in the handle, each manipulation could be independently tested for required torque to turn, and smoothness of operation.

Soldered, fused and welded parts in electrical and electronic assemblies can be difficult to grip in ways that mimic the forces applied when in use, because they are complex or asymmetric. Our client manufactures safety-critical alarms and asked us to provide custom fixtures for pull-out and push-out force testing.

Mecmesin designed an assemblage of fixturing parts for different components under test, in order to correctly align easily them every time. These included a sliding table, a chuck and a cylindrical sleeve holder.

Many flip-caps on flat-sealed cosmetics tubes are not designed for consumer removal, and should not come off under normal use. Pulling them off to test the required force, without distortion through over-gripping, led our client to request a custom fixture.

Mecmesin provided a means of pulling the cap from the inside, a simple but effective solution for reliable and repeatable testing.

A manufacturer of torsion springs approached Mecmesin for a set of custom mandrels. Torsion springs require central core support, and turning pins to engage a wide variety of leg ends.

We regularly design custom torsion spring cores and mandrels to client specification, for operation on our Vortex and Helixa (precision) torque testers.

A manufacturer of hygienic disposal bins came to us with a nappy (diaper) disposal unit with a rotary intake mechanism. The bin was 30 cm wide and the opening at 45 degrees, making holding of the bin for proper axial rotation somewhat difficult.

Mecmesin designed a rotating platform at 45 degrees to rotate the bin about the axis of the rotating mechanism, but the width required an additional modification of our standard Vortex torque tester for increased column separation. The result was a tester for rapid and effective, repeatable testing to ensure consistent quality of the manufactured units.

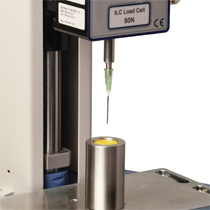

Hypodermic needles can require comparative sharpness testing using synthetic skin, or for the purposes of syringe filling, penetration of closure elastomers such as silicone or neoprene. To do so conveniently, a membrane of uniform thickness elastomer, held under constant tension, can be repositioned for repeat penetration.

For a number of clients, Mecmesin has designed and manufactured custom fixtures for holding hypodermic needle assemblies, and for stretching elastomer sheeting over an aperture for penetration testing. Sharpness is not an absolute value, but the force required to penetrate a vial closure must be consistent, and different point bevels will yield different values. Importantly, during the test, the needle must not flex and the angle of presentation be precise.