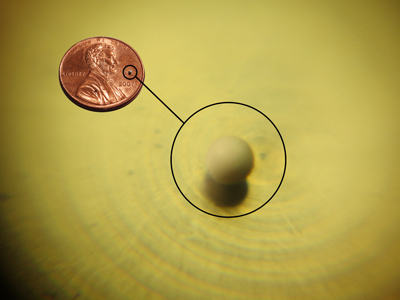

High-purity pharmaceutical alumina sphere

G.T. Michelli Co. serves a wide variety of industries and markets from petrochemical manufacturing to biomedical facilities. The company supplies products and systems in the field of force measurement plus the support services to maintain those applications. A customer needed a new solution to improve both the accuracy and repeatability of measuring the compressive crush force for its alumina sphere products. Used in the chemical industry as efficiency-improving catalysts or in peptization processes, these high-purity spheres of only 0.7 mm in diameter must perform consistently under extreme conditions. The manufacturer has pre-determined specifications for the crush failure characteristics that must be met, and the existing manually-operated stand and gauge system was not providing the required level of confidence.

A single sphere compressed to failure

Mecmesin tested samples of the alumina product, and produced video footage of the process with a detailed report of the measured force characteristics output from the proposed computer-controlled system. Based on this information, G.T. Michelli’s end customer adopted the solution. A single-column Mecmesin test stand and 2.5 kN intelligent loadcell with a self-levelling 70 mm diameter base compression plate and 50 mm upper plate exerts a top load on a single sphere until it cracks. The force on the sphere under load is displayed as a real-time graph and the first-peak failure value captured as the critical data. The product testing is carried out under laboratory conditions and the connected PC running Emperor™ software automates the whole process via the bespoke test program written by Mecmesin engineers. The elimination of human error or variability afforded by the software control is of particular value to the manufacturer. Additional benefits over the previous system are that the test stand’s fixed compression plates require no adjustment, and the crosshead’s upper and lower travel limit switches protect the loadcell from overload damage.

“Our customer’s quality laboratory decided to upgrade their equipment and contacted G.T. Michelli Co. to provide them with a new system. Initially we evaluated a Mecmesin competitor’s system, and it failed to meet the standards required. We had recently sold a Mecmesin torque tester to another customer and so were aware of the force test stands the company manufactures. I contacted Mecmesin’s technical sales engineers and supplied some samples and within days a complete solution was developed and demonstrated. This system now performs our customer’s tests seamlessly, with higher accuracy and less uncertainty than ever before. The system is so easy to use and the software so intuitive that the operator needed very little assistance!”

Patrick Jester, Quality Assurance, Safety & Training, G.T. Michelli Co.