Tear Testing

Tear TestingFabrics, sheets and films tear when a point of weakness fails and propagates, but the nature of a tear depends on the way force is applied and the internal structure of the material. A textile tear is in effect a sequence of tensile breaks in yarn, whereas rubber is more susceptible to material flaws, internal structures and temperature. The main weakness in a finished product may be deliberate, such as an eyelet, stud or button hole. A product may tear differently depending on how it is pulled, in which direction, and whether the weakness propagates from an edge or the middle. Elastic properties play an important part in tear resistance, but test data capture the detail of the tear itself in progress.

Tear test methods require sample preparation, depending on the type of material.

|

|

|

|

|

|

| Winkelmann or crescent |

Graves or angle |

Delft | Trouser | Trapezoid | Tongue |

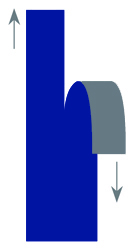

There are many standardised test methods to deal with different materials and conditions, presenting how samples should be prepared, held and pulled apart. In most cases a notch or cut is made to initiate the tear, since the important effect to observe is tear propagation. Test methods prescribe various standard shapes and dimensions of samples for elastomeric samples (called a coupon), or tear preparation types for textiles. Typically rubbers and elastomer samples are die-cut to a standard ‘wing’ shape with a sharp V notch, typically Winkelmann or Graves profiles.

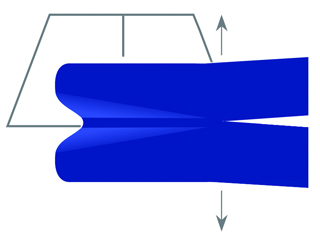

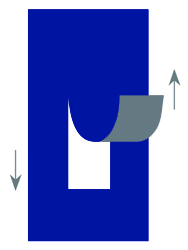

Fabrics or paper are pulled apart axially from either a single cut in the short edge of a long rectangle, to introduce a tear like trouser legs, or by starting a tongue within a fabric rectangle that is pulled out with a double tear. The trapezoidal tear method, by gripping the non-parallel sides in parallel, ensures tear propagation more evenly from a notch introduced in the shortest side.

The standard methods in the textile industry for testing fabric tensile strength, are the strip method and the grab method. In the strip method, apparent elongation and maximum force at rupture are measured by gripping the full width of a sample with ravelled edges (yarns removed from each side) and pulling at constant rate. In the grab method, the sample is gripped in the middle of its width at each end, to a precise grip area, to induce stress forces in the ungripped part of the sample. These are strictly tensile strength tests, not tear tests.

Tearing force can also be applied in different ways: impact (by the falling pendulum method), or uniaxial tension. Mecmesin has a range of universal testers that can meet any of the tensile test methods.