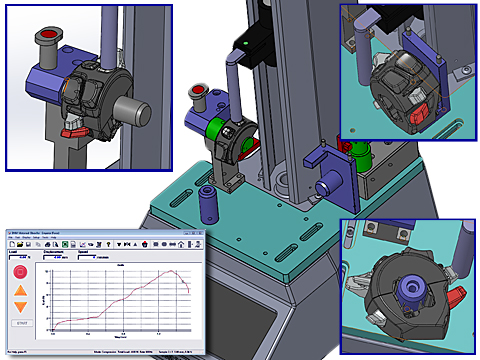

The testing jig was designed to accommodate all sub-assemblies

A leading German motorcycle manufacturer wanted to perform a series of tests to evaluate the actuation forces on its handlebar-mounted controls. The rider of a motorcycle needs to be able to activate the switches with ease, under all driving conditions, in order to operate the bike safely. The controls must also respond with a positive feel, with clear feedback that the function has been performed, whether actuated by the rider’s fingers or thumb. The company required a testing system which enabled each type of control to be tested, whatever the mechanical method of operation or the position and orientation on the bike.

Mecmesin’s engineers worked with the manufacturer’s testing team to design a fixturing system to meet several objectives. In was firstly necessary to secure the component module incorporating the control to be tested so that the direction of motion to operate the switch aligned with the axis of the probe—facilitated by the multiple location points on the test stand’s anvil plate. The small compression plate could then operate the control, whether a push-button, rocker, toggle or lever style of mechanism. Other components of the assembly also needed to be supported in order to test a complete module, representative of a manufactured sub-assembly. The delivered design was a complete test workstation for hand-operated switchgear. EmperorTM software runs the compression test and records the peak force required to actuate the switch. EmperorTM is able to respond to triggered external events via the I/O port of the MultiTest, enabling the linear distance moved to work the control to be easily determined and indicated on the results graph. This test system has enabled the company to continue to design stylish high-quality cockpit controls, combined with excellent ergonomics and safety of operation—for which the brand is renowned. With customer demand for more features and equipment (heated seats, cruise control, infotainment and connectivity, for example) these controls can be developed and located to fall to hand as readily as those for the fundamental functions such as lighting and turn indicators, and operated with ease.

The compression force is measured until the switch actuation is triggered by an external event