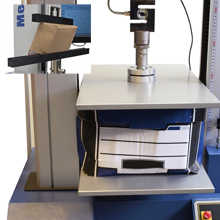

Boxes for the consumer and transit packaging industries must be as light as possible whilst still retaining a robustness to contain and protect their contents and also have the strength to stand up to shipping, handling and stacking requirements in service. The use of corrugation adds rigidity to paper and card packaging materials, which are tested in compression with several crush testing / top-load standards, namely the box crush test (BCT) and the related edge crush test (ECT) and stacking crush tests. Suppliers may also require modified tests to suit specific customer’s needs, as transit packaging particularly can undergo a variety of loading during its journey. The international industry quality assurance procedures for the box compression test may require self-levelling compression plate(s) in order to follow the pattern of failure, or some standards stipulate only the upper must be spherically pivoted to meet this requirement. Other standards indicate rigid compression plates when loading opposite sides (or corners) of the box. The BCT test loads the box at a constant rate to a nominal compressive load, or until the container collapses. In-house testing may use custom fixtures to load the box for unique crush situations such as edge to opposite edge.

Mecmesin Systems: Force test systems

Standards: ISO 12048, BS EN 22872:1993, ISO 2872:1985

Top-load testing PET bottles and containers

Top-load testing PET bottles and containersA consumer packaging manufacturer supplying the leading brands in diverse markets must ensure that their product testing meets the demands of all organisations in the supply chain. For a producer of PET (Polyethylene terephthalate) plastic bottles, part of the total quality control must ensure the axial strength of bottles is continuously monitored (see this article: why test top-load?). The industry demands a responsible approach to minimising raw materials for both cost and environmental reasons, so strength remains critical for the containers, from filling and capping to transport and storage. Top-load (column) crush test systems can be employed at the production line (with a console-controlled touch screen for quick access to relevant test programs) to allow bottles to be sampled at regular intervals. Typically a top loading at 250 mm/min is applied to measure maximum load before buckling. These systems are also used for cap lid pull-off tests and the ease-of-use afforded by a favourites screen permits rapid, repeatable testing at the touch of a button.

Mecmesin Systems: Top-load crush testers, touch screen test systems

Case Studies: Top-load testing PET bottles, top-load automated crush testing PET bottles