Automotive External Mirror Deformation Tests

|

|

|

Automotive side mirror durability testing specification

|

Specification

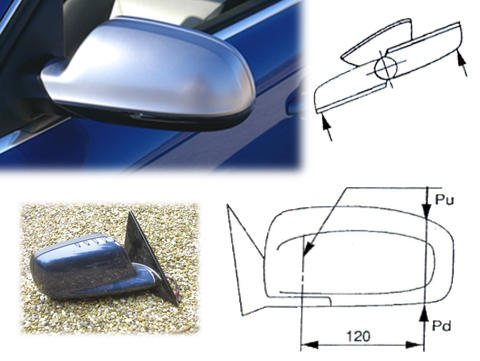

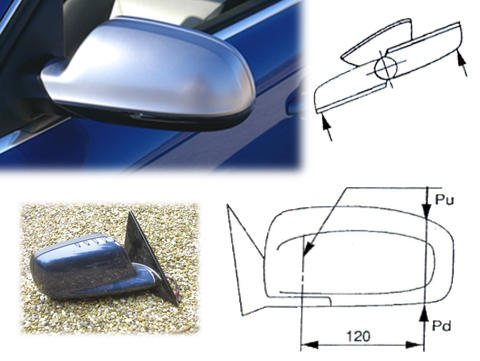

Murakami Ampas (Thailand), is a major supplier of mirror systems to the automotive industry. The company’s expertise with optical filters and actuation mechanisms lends itself perfectly to the manufacture of these complex products. Global brands, Toyota, Honda and Ford, source their external and interior rear-view mirrors from Murakami. As with most vehicle sub-systems, especially safety-related, there are legislative standards that must be met. The challenges of design (style and aerodynamics) and the technology to provide increasingly innovative feature levels specified by the vehicle manufacturer, must be met without compromise to the regulations. The ability to perform thorough functionality and durability testing enables the supplier to provide a complete solution to the OEM customer. External mirrors must fold inwards and stow when needed, either powered or manually, or rotate if subjected to an impact force. In these circumstances, damage should be minimized – both cosmetic and functional.

Solution

|

|

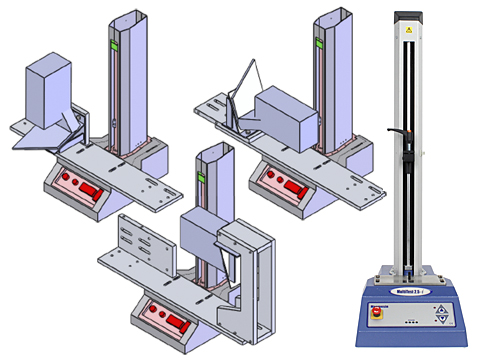

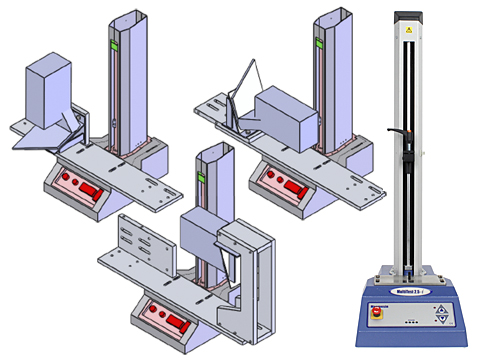

Custom-designed fixture allows all tests to be performed on one test stand

|

Murakami had the requirement to apply forces to the mirror in two distinct

compression tests. A 40 N.m torque is applied about the rotational axis for 1 minute, with no resulting defects in visual appearance or function. A further test applies a 400 N load vertically for the same amount of time and checks for permanent deformation or alignment issues with the rotating mechanism, or other loss in functionality. Mecmesin Thailand supplied a computer-controlled force testing stand with loadcell, and completed the solution with a specially-designed fixture to locate a mirror system and perform both tests. The flexibility to provide comprehensively quality-tested sub-systems is an important capability for a trusted tier one automotive supplier.

System

- MultiTest 2.5-i , MultiTest 1-i PC-controlled test stands

- 250 N, 1 kN intelligent loadcells

- 2-way plane grip (serrated jaws), 50 mm nickel-coated compression plate, QC adaptors