The packaging of wine has great influence on the quality of the product delivered to the customer. Traditionally the method of closure has been the natural, or latterly synthetic, cork stopper. This solution, despite attaining high standards of sealing and taste preservation, can present problems for the end user attempting to remove the cork and reseal the bottle. As a result, the industry has developed alternative screw-cap designs aimed at achieving more consistent and reliable performance. The benefits of newer screw closure designs in the wine bottling industry have brought improved ease of opening, reduction in wine faults and elimination of tainting compared to traditional cork stoppers. Stelvin® ROPP (Roll on Pilfer Proof) caps also add tamper evidence features. Testing the effectiveness of the capping process requires a repeatable method of measuring the removal torque characteristics of the closure system.

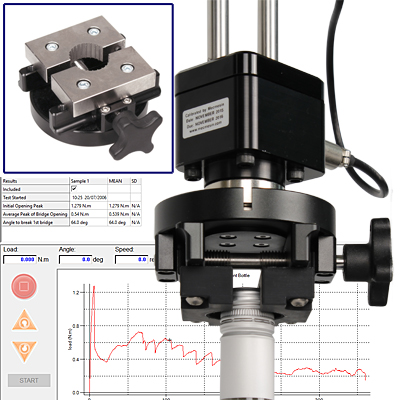

Mecmesin’s Vortex range of torque testing systems, when used with a custom designed split pneumatic mandrel, with rubber-lined serrated cap contact faces, can enable the ultimate accuracy in the cap testing process. A motorised tester provides a consistent rotation speed, while the mandrel eliminates distortion through gripping the metal cap sample uniformly around the circumference of the thread; essential for optimum repeatability in a closure torque test procedure. The software environment, EmperorTM Torque, enables identification of the discrete peaks representing the initial slip/breakaway torque of the closure and the value/angle at which the tamper evident band is breached. A winery is then able to use these data on the bottling line as a verification of the capping equipment’s settings. This closure testing capability ensures the manufacturing facility is able to produce wines and other beverages that are sealed securely and consistently, while the end customer is able to open the bottle with minimum effort, to (responsibly) enjoy the contents.