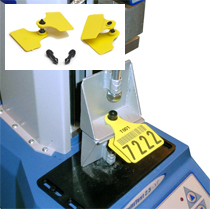

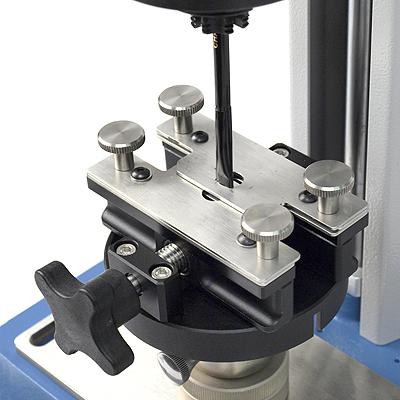

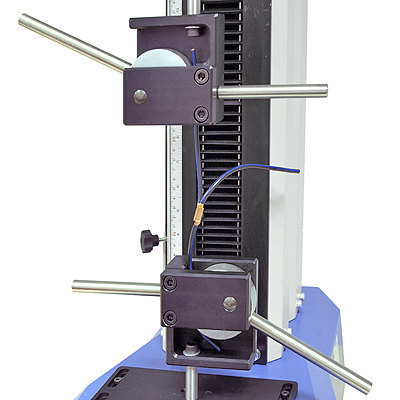

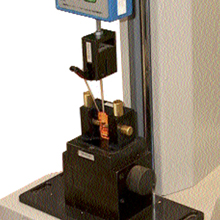

Animal identification tags are important for both legal and health & safety reasons where animal by-products are sold into the human food chain. The tags on dairy cattle are used to record data and trace the animals throughout the milk production process. The tags themselves, attached through the livestock’s ear, comprise of two flexible plastic leaves and a tamper-proof pin fastener. They must remain on the animal – and complete in themselves – when subjected to all expected in-service forces. Specific standards require testing for both tensile strength (by means of a transverse pull test) and pull-off/pull-out forces along the axis of the pin. The software–contolled test stand is able to hold the tags at a target load and then pull further at contolled speed (typically 500 mm/min) until breakage. Once failure occurs, the tags must be unusable as part of the traceability requirements. The transverse pull test can be performed with suitably rated tension wedge grips. The pull-out test on the pin can be achieved with custom grips designed to pull axially and support the leaf surfaces.

Mecmesin Systems: MultiTest console-controlled force test system, 5 kN wedge grips

Case Study: Animal Identification Tags

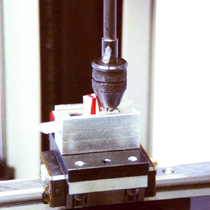

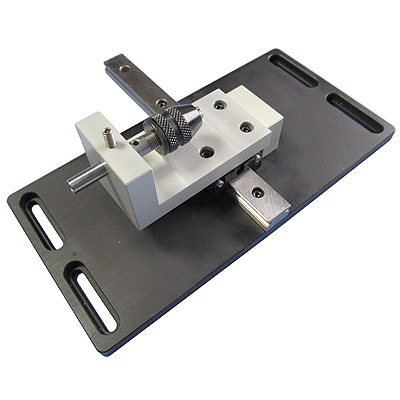

The action of brush bristles in any in-service situation is quite a complex system. Many forces are applied, often in multiple directions and the action of frictional forces also has an impact on the durability of the product. In addition the retention of the bristles (filament shedding performance) is an important consideration. A simple manual toothbrush is subjected to these conditions, as well as industry test methods applicable to cosmetics and personal health – specifically dental equipment standards. A versatile and complete testing solution should be able to perform the bristle stiffness test, in which the complete brush tufted area is rubbed against a metal grid at constant speed – subjecting the bristles to a cantilever bend force. The forces recorded then categorise the toothbrush into consumer categories from soft, through medium, to hard. Shedding performance can be measured by pull-of/pull-out for individual filaments or a ‘tuft’ of bristles with a surgical clamp and a pin chuck fixture, respectively. Location of the toothbrush head should be secure in order to eliminate flexure in the plastic (polypropylene) housing itself. A robust console-operated system would allow testing in a mass manufacturing environment, with simple operation for production staff, giving the confidence to meet stringent quality standards.

Mecmesin Systems: MultiTest console-controlled force test system

Case Study: Toothbrush Stiffness Tester

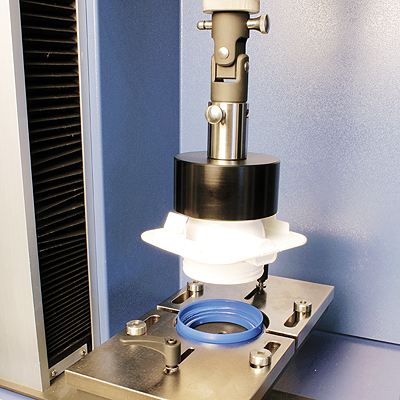

The 6% taper Luer lock-type of connector has widespread use for hypodermic syringes, needles and with certain other apparatus for medical implementations, such as transfusion equipment, for the delivery of fluids. For systems using semi-rigid materials (e.g. plastics), the relevant standards require a specific metal reference conical fitting to be used, either male or female, to test both parts of the connector. The testing of separation (pull-off) compliance requires that the element of the connector under test remains attached to the reference fitting. The Luer component is first applied to the reference fitting by a maximum axial force in conjunction with a precise, small value, maximum torque (27.5 N top-load and 0.12 N.m torque). Once located, the test must apply another strictly axial force away from the test fixture at a constant rate of 10 N/s up to a maximum value of 35 N and for a minimum time of 10 s, in order to evaluate the pass or fail condition for the pull-off test. The subsequent part of the method may require a different test stand to complete the full quality assurance process to acceptable accuracy, due to the significantly different force values to that required to locate the fitting initially. A constant rate of traverse system can achieve the necessary force application rate by prior testing to equate the displacement rate for the sample type under inspection.

Mecmesin Systems: Helixa precision torque test systems and MultiTest motorised test system

Applicable Standards: ISO 594-2, BS EN 1707, BS EN 20594-1 ISO 80369

White Paper: An Examination Of Needle And Syringe Force Testing

Electrical lighting displays which are erected on buildings in public areas, such as seasonal illuminations, are subjected not only to specific electrical standards, but also legislation surrounding their installation, operation and removal. The fastening hooks/eyelets securing the cables to buildings or other structures must resist tension forces designed to test pull-out from their anchoring and tensile strength of the attachment or its bolts. Due to the location of these anchorage points – usually in high-up or relatively inaccessible spots – a test system with the emphasis on lightness and portability is required. The ability to also store multiple readings within the gauge’s on-board memory, ensuring traceability of the measured peak force values back to individual fastenings, should also be a requirement. The data may be analysed offline to evaluate the entire electrical system’s integrity once the gauge has collected the information. For additional safety consideration for the operator, a handle for the gauge should be employed.

Mecmesin Systems: Digital force gauge, manual handling kit

Case Study: Festive Lighting

The performance, durability and safety conformance of clothing must reflect the multitude of styles and materials mix plus functional and decorative additions. These various embellishments: buttons, ribbons, bows, sequins, diamante and other fastenings that have been attached to textiles need to be checked that they have been safely affixed so they will not become choking hazards for infants, for example. The necessary test-to-failure (TTF) indicated by the standards – a code of practice for the design and manufacture of children's clothing to promote mechanical safety – involves pulling the feature until it detaches. The method tests the pull-off/pull-out and tensile strength of the product and also recording the displacement of the crosshead will give a measure of the elongation at break. A selection of grips may be required for securely grasping the decoration – with hooks or slots – depending on the design.

Mecmesin Systems: MultiTest console-controlled force test system, digital force gauge, test hook, popper-cam base

Case Study: Diamante Pull-off Test, Bow Pull-off Test, Button Pull-off Test, Press-Stud Popper Pull-Off Test

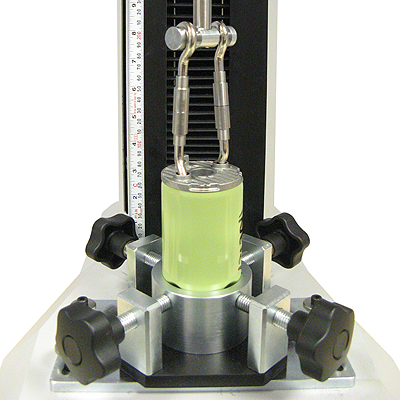

The bung used to stopper a beverage bottle must provide a leak-free seal to protect and preserve the liquid contents, whilst still allowing an ease-of-opening to access the contents. The removal process may involve a combination of pulling force and some rotational torque in practice, however to implement a repeatable quality assurance test, a standard method must employed. The axial force of extraction gives a consistent indication across different samples and provides greater simplicity of test procedure than mixing the pull-off/pull-out force and torque elements. An adjustable clamp to grip the glass bottle and a quick change fixture enable the versatility to test different categories of container from standard to magnum, as necessary. A chain link assembly connected to a suitable cork screw is used to locate into the plug material and apply the tensile load via the crosshead. Software control of the test stand and the ability to clearly indicate a pass or fail condition complete this system for reliable and accurate closure testing.

Mecmesin Systems: Force test systems, Emperor™ (Force)

Videos: Combi Cork Extraction Tester

The butt joint is inherently the weakest category of joint between two components, especially if a reinforced type is not used. The tensile strength of the connection is wholly dependent upon the bonding system, whether this is in contact with raw materials or the adherend is the coating on the surface(s). This type of joint has applications in many industries, from wood-working to large engineering systems. With metal components, welding is an option, however the advantage of a glue-based system is that it allows the full surface area of the butted faces to contribute to the strength. The overall failure of the joint under pull-off loading may be cohesive (where the glue suffers a lack of integrity) or adhesive failure at the glue/coating or coating/material connection. The latter is indicative of deficiency in the coating process, or evidence of the bonding agent having a detrimental effect on the coating. A butt joint test system must be capable of exerting enough force to break the butt joint apart, perfect axial alignment and deal with the possibility of a sudden catastrophic failure of the joint.

Mecmesin Systems: MultiTest computer-controlled 50 kN machine

Case Study: High Performance Plasma Coatings

Zippers (zips, fly, fly fasteners) are used for the fastening together, or binding, of the edges of fabrics, textiles and other flexible materials. Usage in the clothing, furniture, outdoor pursuits and sporting industries is common. The fairly complex mechanical nature of the clasping mechanism, involving interlocking teeth and a hinged pull-tab, requires a set of tests to ensure the quality assurance of the complete assembly. The crosswise (ordinary zipper) strength per 2.5 cm of the chain, tests the peak load that the interlocked teeth can endure before being pulled apart laterally. The webbing at either side of a the chain is securely held with 25 mm wide grips and pulled apart at a constant 300 mm/min. The top stop (zip closed position) and the bottom stop (zip open position) are also tested. The top stop holding strength by holding the lower edge of the interlocked zipper and pulling the slider firmly in the closing direction. The bottom stop holding strength pulls each of the chains apart at right angles to the zipping direction in a manner similar to a trouser tear or T-peel test. The separating unit crosswise strength pulls the webbing apart at the point of the bottom stop with the zipper closed. The slider/tab configuration is also tested for its locking strength—resistance to sliding as a result of the chains being pulled apart—and, for relevant designs, the tab itself is tested for ultimate tensile strength when pulled away from its housing at 90 and 45 degrees. Custom-designed fixtures may be required for the complete suite of tests, primarily JIS-S3015 and ASTM D2061.

Mecmesin Systems: MultiTest universal testers, Customised force testing applications

Our client manufactures liquid bulk carriers with two-part plastic valve closures. The collar is welded to a plastic bag, and the valve closure is fixed onto it by a compression joint. These joints are tested for the force to connect the two, and to pull them apart. The force required can be as much as 25 kN.

Mecmesin designed a collar-retaining plate and flexibly-linked valve attachment to secure both parts without damage or distortion, on a twin-column test stand. The two parts are then pulled apart axially and uniformly, whilst allowing for uneven detachment.

Gripping the base of a shaped glass bottle for a tensile test can present greater difficulties than for torque tests. Our client needed to pull a foil screw cap and tamper-evident sleeve from bottles of various sizes, without slipping at forces exceeding 1 kN. Barracuda grips are available for the cap, but the bottle required custom design.

Mecmesin designed adjustable V-jaws with rubber-edged finger grips that could interleave for smaller bottles yet be wide enough for larger ones. This provided the required grip under tension and axial alignment for the cap pull-off. Gripping samples securely becomes reliable and quick for improved throughput.

Our client manufactures cosmetics brushes for all applications, and so has a very diverse set for bristle integrity testing. Gripping the shaped handles and bristle tips in a repeatable way demanded more than a single standard vice grip.

Mecmesin designed a system of overlapping plates with cutouts for each brush head profile, to gather and trap the bristles uniformly in a vice action, axially aligned under the loadcell. Barracuda grips hold the handles securely for reliable and accurate repeat testing.

Our client was testing the release torque of 20 mm long plastic catheter caps with irregular features to aid finger gripping. The test is performed by hand with a digital torque sensor, but achieving maximum grip and quick insertion required customisation.

Mecmesin designed a multi-finger mandrel to ensure maximum contact and exact axial alignment. This improved the accuracy of the test through repeatability and cost savings through efficiency in use.

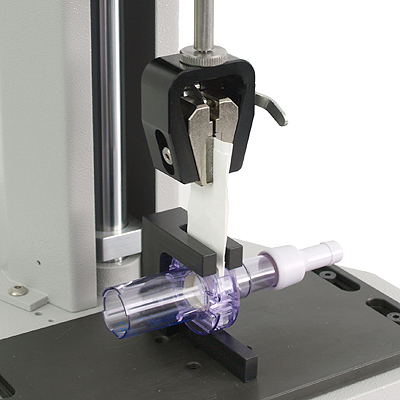

Pull-off tests require careful support of the separating parts to avoid distortions affecting the connection, or breakage due to grips. Several of our clients have needed to test the pull-away force of flexible intravenous tubing from connectors.

Mecmesin has designed fixtures to support the connectors in axial alignment with the gripped tube, for fully repeatable testing and rapid positioning of samples. A simple and cost-saving solution to a common, but specific, test situation.

Test method standard BS ISO 4919 applies to the tuft withdrawal force of carpets. Our client tests artificial grass by the same method, and required custom fixtures for the coarser construction.

Mecmesin's solution was a quick-fit and release clamp plate for the matting, leaving an aperture for a forceps clamp suspended from the test loadcell. Testing is quick, easy and repeatable.

Soldered, fused and welded parts in electrical and electronic assemblies can be difficult to grip in ways that mimic the forces applied when in use, because they are complex or asymmetric. Our client manufactures safety-critical alarms and asked us to provide custom fixtures for pull-out and push-out force testing.

Mecmesin designed an assemblage of fixturing parts for different components under test, in order to correctly align easily them every time. These included a sliding table, a chuck and a cylindrical sleeve holder.

Many flip-caps on flat-sealed cosmetics tubes are not designed for consumer removal, and should not come off under normal use. Pulling them off to test the required force, without distortion through over-gripping, led our client to request a custom fixture.

Mecmesin provided a means of pulling the cap from the inside, a simple but effective solution for reliable and repeatable testing.

Sometimes a client approaches us with a range of requirements for a number of their products. Using their universal testers for a variety of testing, they also need custom and versatile fixtures. Cosmetics packaging, for example, frequently combines design-led profiling with light handling, as in mascara tubes and brushes, attractively-curved lotion containers, and lipsticks. Some of these imply very light rotational torque, others maximum strength in lightweight design, for daily use.

Mecmesin custom grips assure axial alignment, secure holding and minimal deformation that might adversely influence test results and repeatability. In this example, compression, tensile strength and torsion strength were addressed in a suite of fixtures for a variety of popular products.

Push-fit electrical connectors must offer a firm but practical fit. Where vibration is a factor, they must especially not work free, but for maintenance they must be separable without being damaged or damaging other components. For repeatable testing of insertion and withdrawal forces, the connecting parts have to be held securely in alignment, without applying additional gripping forces in the connection.

Mecmesin designed custom fixtures for this client to hold the naked terminal parts and the spade connectors in a way that allowed for rapid test sample exchange and maximum throughput.

A major manufacturer of wire harnesses and connectors approached us for a cost-effective solution to strength testing cables of different diameters and welded joints, up to 1 kN. Standard cam grips to this rating proved too heavy and bulky.

Mecmesin designed narrow-profile lever cam grips for the required application, enabling rapid sample insertion and maximum throughput on a minimum requirement test system.

Some of the simplest applications may not seem so obvious when you face them. A string and tab on a tea bag? Commonly stapled in place, the test should be on the clipping of the string, not the tear strength of the bag itself.

For our client, Mecmesin devised the simple 'tea bag hook' to do just this. A small part, a simple test, but now done efficiently and consistently for daily quality assurance and brand protection.

Polycarbonate Luer locks are push-fitted to glass syringe nozzles with a friction fit. Quality assurance demands that they cannot come free under normal use. They can also be tested for removal torque, but our client wanted a direct pull-off test. This required custom grips for both the glass syringe and the plastic lock so that the one would not break and other not deform.

Mecmesin designed and supplied the fixture pair, allowing rapid placement of samples for efficient throughput. The test became a simple, reliable and repeatable exercise.

A manufacturer of smoke grenades required a means of testing the cap pull-off strength, especially gripping the smooth metal cylinder for up to 5 kN of pulling force. An annular clamp would be needed with penetrating pins to hold the cannister, and in alignment with the applied load.

A four-way grip was designed and manufactured by Mecmesin engineers, with pins penetrating the canister base. This provided a secure and symmetrical grip, whilst pulling the rigid cap off with hooks applied to the two cap holes to measure the peak force applied.

A manufacturer of filtration products needed to test the extraction force of a respiratory filter from an inline holder. A standard wedge grip could pull the filter, but the inline unit needed to be correctly aligned each time for the test.

Mecmesin designed a fixture profiled to the plastic holder, allowing rapid sample insertion and setup for an accurate and repeatable test.

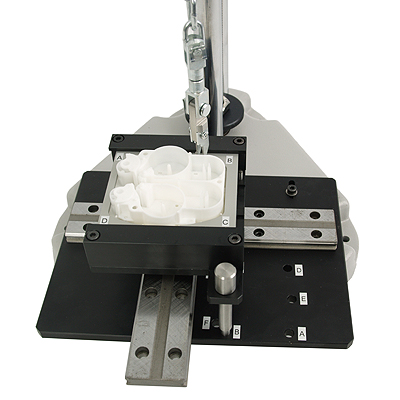

Plastic injection-moulded subassemblies can be clipped or welded, and the integrity of the whole must be tested at several points. However, their shape can make them very difficult to hold, and places to grip for pulling hard to identify. Our client needed a complete custom fixturing solution.

Mecmesin engineers designed profiled nests and retaining plates, an X-Y table for positioning the test sample, and a range of hooks to pass through apertures and engage edges in the assembly. This enabled a defined sequence of pull-off tests to be made consistently across a number of samples for batch testing.

A consumer packaging manufacturer may produce a variety of containers for the cosmetics industry, which in addition to their functional requirement, may have strong design influences. The range of shapes and sizes that result need a versatile quality testing solution to evaluation the effectiveness in sealing plus ease of opening for the container caps. An adjustable clamp, able to securely grip different bottles and jars (possibly made from glass) is needed to measure the torque required to release the lid of the jar. A simple, light and portable digital desktop instrument, measuring the peak value as the lid is released by hand can quickly assess the quality of the screw top closure. For flexible plastic containers, with plastic caps, there could be a danger of the lid being pulled off. A tensile tester with appropriate grips and fixtures will provide repeatable pull-off resistance appraisal.

Mecmesin Systems: MultiTest motorised test system, CAPTEST

Case Study: Cosmetic Packaging Pull-Off Test

Automotive safety-critical systems, such as welds in vehicle airbag connectors, require rigorous testing for zero defects. Pull-off and pull-out testing to destruction at a constant and consistent speed and with complete repeatability enables maximum conformity to quality control standards. To enable the testing to be performed by production staff on the factory floor, special customised quick-release fixtures, enabling batches of test samples to be changed very simply for maximum throughput, enhance the suitability of this solution for automotive assembly applications. Data output is easily achieved from digital gauges for transmission to the organisation’s Statistical Process Control (SPC) software.

Mecmesin Systems: MultiTest motorised test system, digital force gauge

Case Study: Safety-critical welds in vehicle airbags

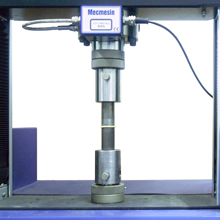

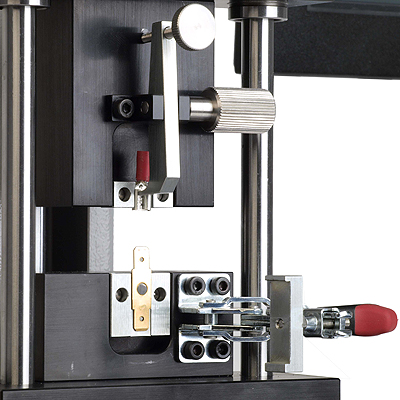

Needle and lancet pull-out testing

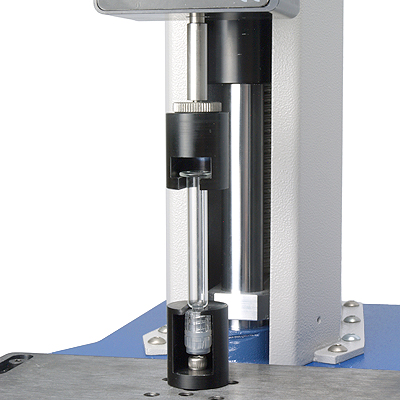

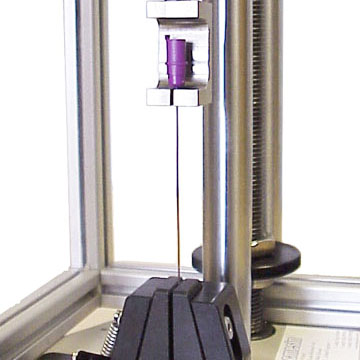

Needle and lancet pull-out testingSurgical needles and lancets may be located in their hub or ferrule by a variety of methods, including bonding, moulding, welding, mechanical interlocking, and sealing. The retention, or pull-off strength of the assembly method must be sufficiently high that the peak frictional force during usage does not cause disassembly or seal failure resulting in the needle remaining in the patient. To test the pull-off/pull-out performance, the test system is normally fitted with a suitable mounting block, to support the hub in such a way as to leave the needle tip exposed vertically. In the case of smaller needles and lancets, a lever-operated pin vice may be used to grasp the tip, and for larger gauge needles, a wedge grip may be required to hold the sample. An axial tensile load is applied at a constant rate, until the needle is completely dislodged from the hub. For safety considerations, the test system should be contained in a protective enclosure to provide protection from the fracture and breakage of sharp objects.

Mecmesin Systems: MultiTest motorised test system, digital force gauges, manual test stands

Case Studies: Lancet needle retention test, needle pull-out test

White Paper: An Examination Of Needle And Syringe Force Testing

Marine vessel aluminium frame fastener shear and pull-out strength

Marine vessel aluminium frame fastener shear and pull-out strengthThe marine industrial construction and engineering sector requires stringent testing of the integrity of the fastening systems employed in sea-going vessels. The materials utilised may also be particularly specialised and light weight, thus needing rigorous evaluation to ensure confidence in the strength of the assembly. A bolted aluminium structural element may be tested to accurately simulate its loading in the complex operational environment in order to measure the critical strength of the entire bolted assembly. The weakest element could be the fastener itself, suffering shear failure, or pull-out, or the hole in which the bolt is located could undergo deformation due to the tensile forces and compromise the structure. This testing is thus able to evaluate the lap joint’s performance and provide objective data as to the quality of the batch of supplied fastenings or any modifications to the frame’s cross-section, design or material specifications. Typical shear forces up to 10 kN are able to be handled with appropriately rated wedge grips and a suitably cut-down sample.

Mecmesin Systems: MultiTest motorised test system, 10 kN wedge grip

Sheet metal welded fastening pull-off failure

Sheet metal welded fastening pull-off failureThe fabricator or supplier of sheet metal products for the construction industry must ensure that the material is able to withstand the forces that may be encountered in all downstream processes in which the raw components may be used. The integrity of fastening systems used in complete assemblies or joints will be influenced by the basic material properties and the characteristics of any coating, such as a non-corrosive treatment. The testing to failure of welds to ensure they remain sound and crack-free in service provides vital feedback into the manufacturing process and allows the confident specification of welding parameters for safe usage of the raw steel. The use of a computer-controlled testing system to record the peak force incurred before pull-off failure enables quality compliance to internal or international test standards.

Mecmesin Systems: MultiTest motorised test system

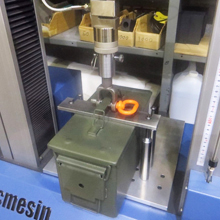

Metal case handle and lock hasp operational strength

Metal case handle and lock hasp operational strengthThe functional attachments of transit packaging products: handles, locks, latches, hasps and clips, etc. are essential to the operation of the container. In the case of a military implementation – such as an ammunition case – it is imperative that these components perform as intended. The non-destructive testing of every production item for such a critical article, would also require a system that can hold the container securely yet allow swift change-over time between tests. In order to test both the handle and hasp of the locking mechanism for resistance to pull-off forces or material failure under tensile load, large and robust custom fixtures are required to grip the unusually-shaped features of the case. A console-operated test stand is suitable for a production environment, with the test programs able be run from a touch-screen icon to then apply the required load value for each element.

Mecmesin Systems: MultiTest touch-screen test system