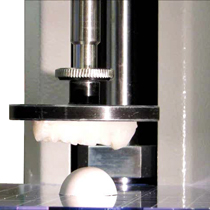

Scientific research in the sphere of physiology, anatomy and medicine has far-reaching impact on the health and well-being of humankind. The methodical application of testing and investigation into how biological systems behave and react to change allows the furtherment of medical science. The discipline of dentistry can employ mechanical testing to evaluate the bite strength of the mandible/maxilla system throughout the aging and wearing process, by repeatable compressive strength tests. One specific example uses a computer-controlled test stand to compress a plaster of Paris dome-shaped sample (which has comparable mechanical properties to hard, brittle food items, like nuts) to measure ultimate bite strength. Dental model attachments to the compression plate represent the tooth profile within the jaw and in addition to the force measurement, further evaluation of the fractured sample – size and number of fragments - also influence the scientific appraisal of mechanical performance. As the teeth wear, the profile changes and the effectiveness over time of the ability to fracture the foodstuff can be determined. The test program records the peak force at fracture and uses stop-at-break functionality to avoid damage and reset, then the output data is further analysed in Excel® - allowing the flexibility to continue research out in the field, by use of portable computers. The Emperor™ software’s ability record all of the data is invaluable in the thorough understanding necessary in a scientific project. Furthermore, this ethical engineering solution negates the need to experiment with living primate specimens.

Mecmesin Systems: MultiTest computer-controlled force test system, compression plate accessory

International sports organisations are responsible for the regulations governing their field of interest and these may cover a wide range of unique requirements. The sport of tennis has a number of court surfaces and also player levels from recreational through to professional which determine different criteria in terms of tennis ball characteristics. The fundamental performance measure of a ball is the bounce behaviour and this is directly influenced by its compressive deformation, size and weight. A customised automated computer-controlled system which is able to pick an individual ball and perform the compliance test, without human interaction, whilst capturing the results to generate a statistical report can then become an official approved test standard. In terms of the test specification for a tennis ball, the program steps include touching on the surface, exercising scragging before measuring the force through compressing to a specified ‘forward deformation’ (and relaxation) in 3 orthogonal axes. The process involves complex steps involving holding to certain load levels for certain amounts of time plus diameter and weight measurement. Challenges such as physically picking the next ball and moving the supply along require bespoke engineering solutions involving pneumatic grips able to grasp and to rotate to XYZ alignments, custom compression plates, a carousel dispenser and digital scales.

Mecmesin Systems: Customised force testing applications, Emperor™ (Force)

Case Study: Automated ITF tennis ball tester

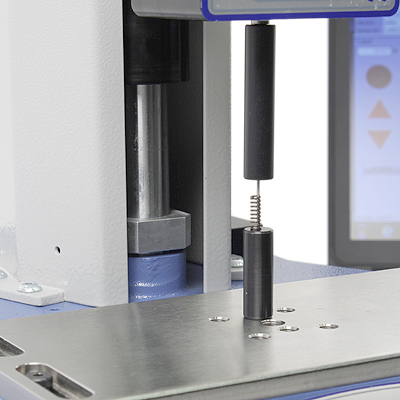

Keypad push-buttons are important componentry on many electrical and electronic products. Mobile phones, keypad entry systems or industrial machine controllers all have functional reliance on the reliability and longevity of these components. Testing the life-span for the keypad through repetitive actuation of the buttons requires automation to repeat the compression test cycle to either failure detection, a measured drop in the value of a significant parameter, or a specific number of cycles – at which point the component may be inspected visually and for degradation in functionality. A simple force gauge may be used to determine appropriate loading. The added flexibility of being able to specify the correct compressive force for different keypad implementations can be programmed into a software-controlled system.

Mecmesin Systems: Digital force gauge, Emperor™ (Force)

Case Study: Mobile Phone Keypad Life Test

Medical device manufacturers operate in one of the world’s most competitive and highly-regulated industries, where success and lives hinge on compliance to standards, time-to-market and results traceability (raw data retention). A robust audit trail is important for the OEM if the customer has a product problem in the future. Syringes must deliver and extract fluids in a smooth, controlled manner; a plunger that is too easy or hard to actuate, or that stalls or judders on depression will not perform reliably during injection or aspiration. The testing of manually operated sterile single-use hypodermic syringes for glide (in both aspiration and expression strokes) force is essential under industry standards. These forces will be determined by a range of variables, the size of the syringe/needle aperture, the ‘fit’ of the plunger within the syringe barrel, the materials used and, in service, the density of the tissue substrate and the viscosity of the liquid. The syringe must be developed with the optimum balance of these variables to assure consistency and usability. Typically, a constant rate of plunger depression (and withdrawal) of the order of 100 mm/min is indicated for this test. A compression tester should be employed that deals with security – a log on for operator identification - and software to accurately control the plunger displacement and record the data. A fixture to grasp the finger flange for tension and compression strokes, with adjustability for syringe sizes, may also be required.

Mecmesin Systems: Touch screen test systems, Emperor™ (Force)

Video: Syringe plunger actuation force

Standard: ISO 7886-1

Moving components in transportation systems are critical in the safety of the passengers using the systems. Doors, windows, shutters and other sub-systems that open and close are all potential sources of accident or injury through misuse or potential malfunction. A public transport system, such as a train or similar transit vehicle with multiple carriages and sliding flush-fitting entry/exit doors would require a portable and simple, but representative test procedure to measure the maximum pinch force of all the doors. An effective solution involves a custom, cantilever activated arrangement which can be placed safely (for the operator) between the doors and loads the digital force gauge. The selected gauge, dependent upon features and functionality, may be set to immediately register a pass/fail result and audio warning.

Mecmesin Systems: Compact digital force gauage (CFG+), Advanced Force Gauge (AFG)

Case Study: Train Door Closing

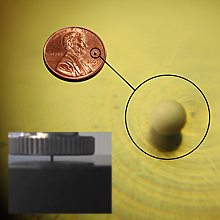

Crush strength is the peak compressive force required to take a sample to its [ultimate] compressive strength at which the onset of failure occurs. A single pellet crush test could be applicable to products such as pharmaceutical tablets (or similarly shaped confectionary), ceramics and industrial catalysts formed of solid material. The implications of failure in these industries is of varying degrees of impact – the industrial catalyst may result in plant shutdown and thus stringent testing is required. The physical shape of the pellet affects the exact test standard method: tablets and spheres being crushed by a different method to extrudates, granular or irregular shaped products. To accurately measure the mechanical properties of a single sphere under load, the use of self-levelling compression plates should be employed. A computer-controlled test stand will enable the first peak load to be captured as the sphere fractures and provision to avoid overloading of the loadcell as the fixture attempts to move beyond this point should be considered. Some examples of the spherical carrier are less than 1mm in diameter and control of the crosshead’s displacement is essential – either physically or by means of the software.

Mecmesin Systems: MultiTest computer-controlled force test system, self-levelling compression plates

Case Study: Alumina Sphere Crush Test

The majority of syringes are single use, disposable and manually operated. Consistency in plunger operation (smooth, and to a correct pressure) is essential, so quality testing requires representative gripping of barrel and plunger, and complete repeatability. Glide force testing can include both filled and empty syringes.

Mecmesin designs custom fittings for syringes of all styles and sizes to ensure a secure grip of both parts without distortion and correctly aligned. For filled syringes, these include fluid collection. Testing becomes both quick and repeatable.

Bard Ltd services its biopsy injector units, which are driven by a powerful spring, primed and triggered by finger pressure. To verify spring strength in units returned for servicing, they must be held in such a way that the trigger can be compressed as in use by hand.

Mecmesin devised a custom fixture featuring a quick clamp and stirrup pull bracket. Placing units for programmed testing is quick, easy and reliable, increasing throughput and ensuring complete repeatability.

With a sensitive digital force gauge, such as the Mecmesin Advanced Force Gauge, a manually-operated test stand can be sufficient for small spring testing in compression or tension. For the lightest springs, very fine control is needed, and the standard gearing may be inadequate for fully-repeatable conditions.

With a sensitive digital force gauge, such as the Mecmesin Advanced Force Gauge, a manually-operated test stand can be sufficient for small spring testing in compression or tension. For the lightest springs, very fine control is needed, and the standard gearing may be inadequate for fully-repeatable conditions.

Propellants are avoided for many reasons in liquid and spray dispensers, with manual spring-loaded pumps used in their place. These are shaped for finger operation, and filled containers give a more reliable operational test. So how do you repeatedly test an awkward and messy pump dispenser?

Mecmesin met a client's needs with a custom designed bottle holder, and collection bin in stainless steel. This efficient solution ensured correct alignment, secure gripping under compression, and cleanliness.

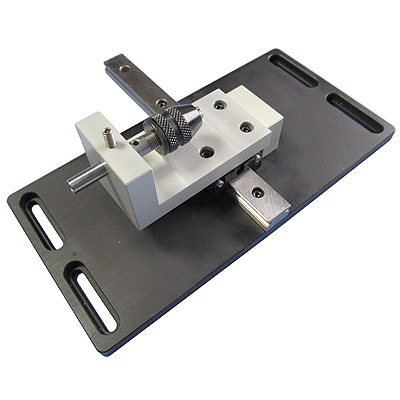

Our client needed to test a number of small, lightweight springs under compression. To avoid buckling and sideways movement in the springs, a supporting spindle or spigot was required, to the dimensions of the springs under test.

Mecmesin designed and supplied compression probes with supporting pins, for operation on one of our regular MultiTest stands. These enabled rapid insertion and repeatable testing.

In addition to top-load carton crush testing, the compressive strength across opposite edges can be an important measurement. This represents a typical shelf and stacking situation where damage can occur from falling. Holding a carton for this test without slippage requires custom fixtures to achieve the correct length and angle of applied compression.

Mecmesin has met these requirement for a number of clients, with custom-designed V-profile compression bars. These ensure the same angle of testing, along the length of the carton to be compressed, for perfectly repeatable testing.

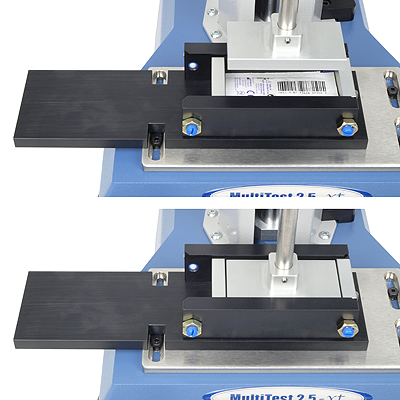

Plastic sachets with welded seams are frequently used for measured applications of liquids, creams and gels. A quick quality test for their integrity involves compression either to burst, or to resist a defined compressive force. This may require containment for spillage, but also for alignment. Our client was testing pharmaceutical sachets.

Mecmesin designed a sliding container, engaging under the test compression plate with ball catches for exact axial placement. This enabled quick exchange of test samples for maximum throughput and repeatability.

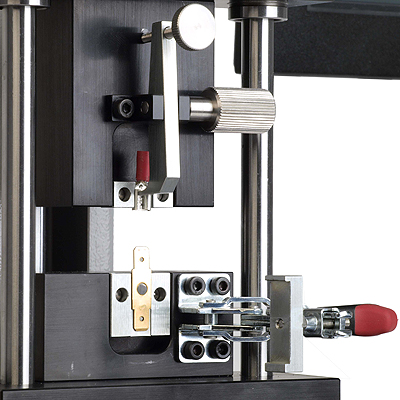

Soldered, fused and welded parts in electrical and electronic assemblies can be difficult to grip in ways that mimic the forces applied when in use, because they are complex or asymmetric. Our client manufactures safety-critical alarms and asked us to provide custom fixtures for pull-out and push-out force testing.

Mecmesin designed an assemblage of fixturing parts for different components under test, in order to correctly align easily them every time. These included a sliding table, a chuck and a cylindrical sleeve holder.

Sometimes a client approaches us with a range of requirements for a number of their products. Using their universal testers for a variety of testing, they also need custom and versatile fixtures. Cosmetics packaging, for example, frequently combines design-led profiling with light handling, as in mascara tubes and brushes, attractively-curved lotion containers, and lipsticks. Some of these imply very light rotational torque, others maximum strength in lightweight design, for daily use.

Mecmesin custom grips assure axial alignment, secure holding and minimal deformation that might adversely influence test results and repeatability. In this example, compression, tensile strength and torsion strength were addressed in a suite of fixtures for a variety of popular products.

Push-fit electrical connectors must offer a firm but practical fit. Where vibration is a factor, they must especially not work free, but for maintenance they must be separable without being damaged or damaging other components. For repeatable testing of insertion and withdrawal forces, the connecting parts have to be held securely in alignment, without applying additional gripping forces in the connection.

Mecmesin designed custom fixtures for this client to hold the naked terminal parts and the spade connectors in a way that allowed for rapid test sample exchange and maximum throughput.

A fibre cable solutions provider needed a custom compression fixture to test plastic ducting strength. Mecmesin engineered a part to fit the inner profile to the required length

This is just one of many examples, where creating a fixture to fit a specific profile, or to insert into a manufactured part, solves all the problems of trawling catalogues of grips and fixtures for an approximate fit that may in the end yield inconsistent results.

It's straightforward: you need self-levelling compression plates but you can't find the appropriate size as standard. Our client was performing flat crush (FCT) and edge crush (ECT) tests on cardboard for cartons.

Mecmesin regularly designs fixtures to custom dimensions, and in this case supplied the precision parts to the client's specifications. Whether compression plates, tensile grip jaws, custom hooks or torque grips, our apllications engineers are always on hand to meet the need where off-the-shelf products aren't suitable.

A UK train operator needed a method of testing the obstacle detection sensitivity of carriage sliding doors. They already had a method for adjustment, but needed to measure the forces acting between stalled-opening and stalled-closing door leaves that would not interfere with their test brackets.

At Mecmesin we devised a sliding bracket to house a digital Advanced Force Gauge, attached by four quick-release suction cups. Attached across the open-door gap, the force required to open and restall the doors could be measured, allowing readjustment and remeasurement.

An aerospace engineering client needed to measure the pinch force between welding electrodes. Clearly something accurate, small and portable was required, operable single-handed, and affordable to be deployed around the fabrication shop.

Mecmesin designed a cantilever to match the electrode gap, which fitted to our CFG+ digital force gauge. Insertion between the weld tips allowed rapid readings of peak force in order to adjust and maintain, with minimum disruption.

British Gypsum carry out repetitive penetration tests to accurately assess the performance and durability of their products. The test, into the edge of plasterboard samples, is repeated sequentially along the board at fixed positions.

Mecmesin supplied a custom automated system, capable of up to 50 sequential edge penetrations per board test sample. The pre-programmed system provides complete consistency and control in penetration separation (indexing), penetration depth, and penetration force, capturing detailed data for full analysis.

Coil springs as used in the transport industry or other general engineering applications may be elements of safety critical components, particularly in public transport (suspension system) or aviation (brake unit) implementations. To evaluate the performance of helical springs under load, the compression test equipment must ensure that the axis of compression remains constant. A coil spring will tend to lean and become out of square under load. Self-levelling compression plates and fixtures custom-designed to constrain and locate the spring must be used. Safety guarding should be a feature of the test system for large powerful springs.

Mecmesin Systems: MultiTest computer-controlled and console operated compression testers

Case Studies: Aircraft brake unit spring testing, railcar spring testing, bespoke spring design and manufacture

The effective actuation of fundamental controls is essential for safe operation of any vehicle. Foot pedals controlling the acceleration, braking and the clutch for manual gear changing, must be able to be depressed with ease by a complete anthropomorphic data range of driver/operator. Measurement of the pedal actuation effort is vital to performance testing of these systems, in terms of reliable operation; the input force must trigger the componentry to apply the brakes, move the throttle linkage or disengage the clutch. Additionally, pedal force testing enables useful evaluation of pedal “feel”, which provides feedback to the user regarding the need to confidently apply more or less actuation force and also conveys information about product quality. Mecmesin has supplied pedal force sensor systems to automotive OEM industry suppliers and testing services, enabling the measurement and data acquisition of these pedal force characteristics to guarantee performance against quality standards. The compact smart load button cell and portable AFTI gauge can be use in confined operating spaces whilst the first peak and maximum recorded data can be stored in the gauge prior to export and further analysis.

Mecmesin Systems: AFTI Advanced Force and Torque Indicator, Customised applications service

Automotive customers demand reliability and quality from their purchases; an owner’s vehicle often an extension of their personality. Brand loyalty depends on many interactions between the user and all elements of their vehicles. Experiencing the tactile feel of controls, switches and buttons are the most common instances where an owner judges the quality level of the product. Ease of application, positive engagement and consistent performance over the lifetime of the component are essential design criteria. One user-centric control is the remote locking key / key fob. Actuation of the button must be simple to perform, and the control give a clear indication that the inner switch has been activated. The force to depress the button must also be high enough to avoid accidentally being activated to eliminate the risk of leaving the vehicle unlocked. Using a light capacity intelligent loadcell and a narrow diameter compression probe, Mecmesin enabled the actuation force of the small, finger-tip sized buttons to be compression tested. Tests can be run for adherence to design specification for pass/fail values or repeated cyclic testing for durability.

Mecmesin Systems: Force testing systems range

Verification of consistency is vital in the initial stages of the concrete curing process in order to ensure maximum compressive strength. The measurement of compressive strength development over time provides verification against the J1, J2 and J3 classes of sprayed concrete. During the early phases, two test methods are applicable, with multiple needle penetration tests being used in the initial stage (typically the first 3 hours or so after spray application) where the calculated strength falls below 1.5 MPa. The method consists of several iterations of ten resistive penetration force readings (to 15 mm depth) taken in rapid succession – under 1 minute – which are averaged to obtain one value in Newton. Typically 5 or 6 iterations would be performed within the initial time frame. A conversion curve (or formula) is then used to find the equivalent compressive strength value in MPa. The curve itself depends upon the mix design, influenced by the size of aggregate, for example. The results are then plotted on a time against compressive strength graph. The standard defines the specific dimensions of the penetration needle as 3mm diameter with a 60 degree taper angle. A digital penetrometer, with handles, oriented display and the ability to store peak force readings provide a convenient, robust and portable solution for use on-site.

Mecmesin Systems: Shotcrete Penetrometer

Standards: BS EN 14488-2, ISO 14488

Biopsy needle injector gun spring strength

Biopsy needle injector gun spring strengthA biopsy stylet and cannula injector gun is a medical appliance for quickly and reliably extracting a tissue biopsy sample. A prime component in this hand-held device is a powerful spring, which is compressed by a single finger trigger action. The tolerances for the compressive spring rate are very specific - low enough to allow a user to operate the mechanism and cock the gun, yet high enough to perform a full and effective insertion and withdrawal of the needle. Stringent compressive strength testing standards require multiple tests on each injector gun to ensure repeatability and reproducibility at the quality control stage of production or refurbishment. A bespoke fixture to simulate the finger and apply the trigger pressure, whilst holding the medical device securely may be needed.

Mecmesin Systems: MultiTest motorised test system

Case Study: Biopsy injector spring strength

Physiological measurement of joint exertion force

Physiological measurement of joint exertion forceMedical and veterinary facilities can utilise force testing equipment to evaluate the capabilities of human (or animal) subjects for any number of research projects. One purpose may be for the collection of data as input to the design of occupational health and safety products or equipment. In the specific example of the range of joint strength in patients' big toe (the metatarsophalangeal joint), the angle of the toe may also be significant. A bespoke testing platform incorporating an intelligent loadcell, would be required to allow the positioning of the foot consistently and hold the toe at measurable, variable angles. A portable digital gauge could be easily employed to capture the data from individual patients over time, and the compressive strength results analysed and used for research or educational purposes.

Mecmesin Systems: Advanced Force Gauge, S-Beam loadcells

Case Study: Physiological Measurement of Joint Strength